Ductile Iron Professional Bridge Tensioning Anchor Prestressed Anchor Round Porous

-

Highlight

Professional Bridge Tensioning Anchor

,Ductile Iron Bridge Tensioning Anchor

,Prestressed Anchor Round Porous

-

AutomationSemi-automatic

-

PC Strand1-15holes

-

Transport PackageWooden Box

-

Wedge Form2 Chip Or 3 Chips

-

CertificationCE; ISO

-

After-sales ServiceTracking Guidance & Service

-

WarrantyOne Year

-

MaterialDuctile Iron

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE; ISO

-

Minimum Order Quantity1

-

Delivery Time7-15Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

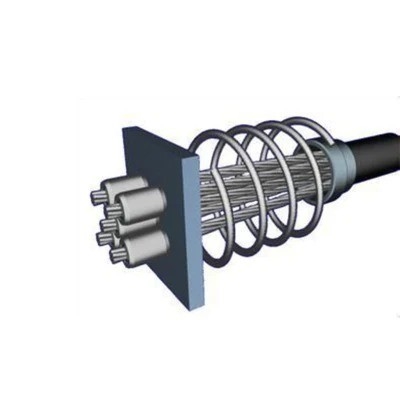

Ductile Iron Professional Bridge Tensioning Anchor Prestressed Anchor Round Porous

Professional Bridge Tensioning Equipment Prestressed Anchor Round Porous

Technical parameter of Bridge Tensioning Equipment Prestressed Anchor

![]()

Introduction of Bridge Tensioning Equipment Prestressed Anchor

Anchorage refers to a permanent anchoring device used in prestressed concrete. It is an anchoring tool in a post-tensioned structure or component to maintain the tension of the prestressed tendon and transmit it to the interior of the concrete. It is also called a prestressed anchor. Tool.

Anchors can be divided into two categories according to the type of use:

(a): An anchoring tool that is installed at the end of the prestressing tendon and can always keep the prestressing tendon in an anchored state during the tensioning process of the prestressing tendon.

Tension end anchorages can also be divided into clip-type anchorages (YJM) for tensioning prestressed steel strands, steel tapered anchors (GZM) for tensioning high-strength steel wires, Pierhead anchors (DM) for tensioning high-strength steel wire after heading, nut (YGM) for tensioning finish-rolled rebar, cold-cast heading anchor (LMZ) for tensioning multi-strand parallel wire bundles, etc. Many types.

(b) Fixed end anchorage: An anchorage installed at the end of the prestressed tendon, usually embedded in concrete and not used for tension, also known as squeeze anchor or P anchor.

![]()

Application fields of Post-tensioned Prestressed Anchor

Highway bridges, railway bridges, urban interchanges, urban light rails, high-rise buildings, water conservancy and hydropower dams, port terminals, rock mass slope protection anchoring, foundation reinforcement, tunnel mine roof anchor roof, prestressed grid, subway, large buildings, halls, Warehouse workshop, tower building, heavy lifting, sliding film intermittent propulsion, bridge, and tunnel jacking, large containers and ships, sleepers, replacement of bridge supports, bridge and building reinforcement, steel reinforcement works, anti-magnetic and anti-corrosion works (fiber anchors) ), carbon fiber reinforcement, pre-tensioned beam field construction, external prestressing engineering, stay cables, suspension cables, etc.

![]()

General anchorage construction and installation method

The general anchorage construction and installation method are to put a small number of explosives at the bottom of the hole, expand it into a spherical shape after several anchorage constructions and installations, and finally put the explosives into the anchorage construction and installation. Compared with the hole anchorage construction and installation method, this method has the advantages of good anchorage construction and installation effect, high work efficiency, fast progress, and low consumption of explosives. This method is often used in the construction and installation of short pile anchors for shallow foundations.

Warm tips

1. The anchors should be kept properly, and there should be no rust, water, and other sundries in use.

2. Apply lubricant on the outer surface of the tool clip and the inner surface of the taper hole of the anchor plate before use, and often remove the debris on the surface of the clip.

3. Safety measures should be taken during tensioning, and no one can stand after the tensioning jack.

4. The anchor system should be used together and cannot be mixed with other systems.