Custom 40m/Roll Beaded Diamond Wire Saw For Reinforced Concrete Cutting

-

Highlight

40m/Roll Beaded Diamond Wire Saw

,Custom Beaded Diamond Wire Saw

,Reinforced Concrete Cutting Wire Saw

-

ColorBlack

-

StyleClassical

-

ApplicationVarious Rock Materials

-

Material40m/roll

-

BrandZHONGTUO

-

After-sales ServiceTracking Guidance & Service

-

WarrantyOne Year

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE; ISO

-

Minimum Order Quantity1

-

Delivery Time7-15Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

Custom 40m/Roll Beaded Diamond Wire Saw For Reinforced Concrete Cutting

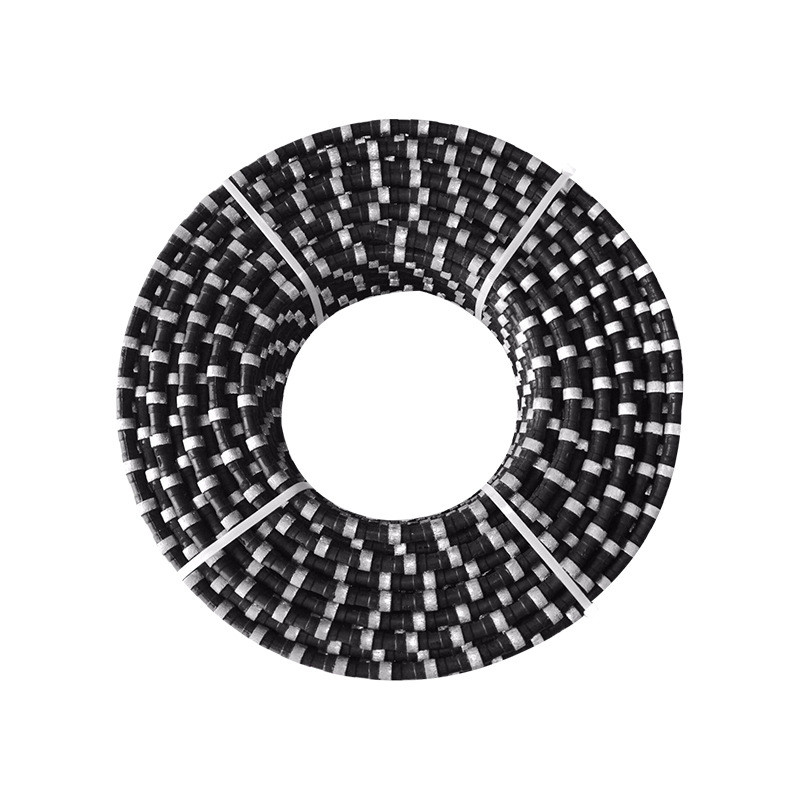

Beaded Diamond Wire Saw for Reinforced Concrete Cutting

Description of Beaded Diamond Wire Saw

The selection of diamond beaded rope is related to the type, hardness, and other factors of the material to be cut. The best cutting effect and longest service life can be achieved by selecting the beaded rope properly. According to the type of cutting, the cutting of beaded rope is divided into mining cutting, shaping Cutting, plate processing cutting and special-shaped product processing cutting, and other types.

According to the type of equipment used, beaded ropes can be divided into beaded ropes for mobile wire saw machines for mining, beaded ropes for stationary wire saw machines for shaping and plate cutting, beaded ropes for special-shaped processing, Beaded ropes for multi-wire saw machines for panel cutting and beaded ropes for concrete demolition cutting.

Technical Parameters of Beaded Diamond Wire Saw

| Diamond wire saw for concrete | |||||||

| Product Model | Bead Specification | Number of beads | Connection | Cutting Materials | Line Speed (m/s) | Cutting Speed m3/h) | wire life (m3/m) |

| GD-11 | Ø11.5 | 40 | Rubber+Spring | High-strength reinforced concrete | 22-25 | 1-3 | 2-4 |

| GD-12 | Ø11.5 | 40 | Rubber+Spring | Underwater reinforced concrete | 20-23 | 1-2 | 2-3 |

| GD-13 | Ø11.5 | 40 | Rubber+Spring | Steelworks or structures made of other metals | 19-21 | 0.8-1.5 | 0.8-2 |

| Diamond wire saw for Granite | |||||||

| Product Model | Bead Specification | Number of beads | Connection | Cutting Materials | Line Speed (m/s) | Cutting Speed m3/h) | wire life (m3/m) |

| GD-21 | Ø11.5 | 40 | Rubber | Hard Granite | 26-35 | 5-8 | 8-18 |

| GD-22 | Ø11.5 | 40 | Rubber | Medium-hard granite | 30-40 | 8-18 | 18-25 |

| GD-23 | Ø11.5 | 40 | Rubber | Soft granite | 35-45 | 18-25 | 28-45 |

| Diamond wire saw for | |||||||

| Product Model | Bead Specification | Number of beads | Connection | Cutting Materials | Line Speed (m/s) | Cutting Speed m3/h) | wire life (m3/m) |

| GD-31 | Ø11.5 | 40 | Rubber | Hard Granite | 30-35 | 8-15 | 25-35 |

| GD-32 | Ø11.5 | 40 | Rubber | Medium-hard granite | 35-38 | 10-18 | 40-80 |

| GD-33 | Ø11.5 | 40 | Rubber | Soft granite | 35-42 | 18-25 | 100-150 |

![]()

Beaded Diamond Wire Saw features

1. Marble, limestone, limestone, and other softer stones are suitable for spring and sintered or electroplated beaded fixed wire saws. For granite, Gabbro, and other hard stones, we use injection molding between beads or rubber injection. If it is used for more demanding cutting (such as cutting concrete), springs are usually added between the beads and then injection molding or rubber injection molding is performed.

2. Granite mining: mainly suitable for rubber and injection-molded wire saws, it can protect the internal wire rope well and increase the tensile strength of the wire saw.

3. Marble mining: Three types of wire saws can be used: spring, injection, and rubber.

3. Diamond combination wire saw: widely used in cutting all kinds of granite slabs.

4. Reinforced concrete cutting wire saw: widely used in the field of construction, can cut houses, bridges, large piers, cement pipes, and underwater buildings.

![]()

Advantages of Beaded Diamond Wire Saw

1. Customize different formulas and guarantee performance cost according to the mixing percentage of hard, medium, and soft( Determinants: content proportion of steel and concrete hardness ) all kinds of reinforced concrete, in order to maximize the performance.

2. Fine-selected diamond with great strength and toughness ensures the sharpening feature and lifetime of the diamond wire.

3. Sophisticated sintering technology with well-controlled temperature and pressure guarantees the diamond beads with great anti-abrasiveness features.

4. Mature injection technology and production technique make sure the plastic enter into every gap of the cable and holds the diamond beads with firmness.

5. Self-developed automatic production equipment and strict inline and final inspection control the quality and stability.

Precautions of Beaded Diamond Wire Saw

1. Regularly check the rotation of the wire saw and adjust it in time

2. Regularly check the wear of the beads to avoid eccentric wear. Once eccentric wear occurs, measures must be taken in time.

3. Regularly check the wear of the joint and the beads at both ends of the joint, and replace the joint in time.

4. The tension of steel rope is generally 250-300kg (Φ4-5mm steel wire rope)

5. The linear speed of the wire saw is adjusted according to different stone types:

Grade 1-2 granite: 25-30 m/s

Grade 3-4 granite: 22-26 m/s

Grade 5 granite: 20-24 m/s

Marble: 30-45 m/s

Abrasive rock: 30-35 m/s

6. In the initial cutting stage of the new rope, its linear speed should be reduced by 2-3 m/s than the above mentioned, so as to facilitate the beading.