-

Highlight

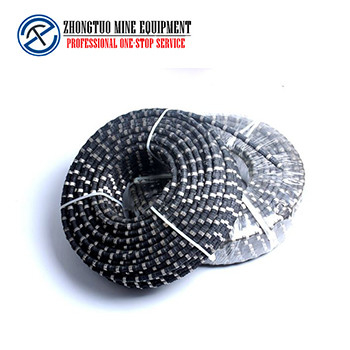

Hard Marble Stone Diamond Wire Saw

,40m/roll Stone Diamond Wire Saw

,Granite Diamond Cable Saw

-

ColorBlack

-

StyleClassical

-

ApplicationVarious Rock Materials

-

Material40m/roll

-

Cutting MaterialHard Marble

-

After-sales ServiceTracking Guidance & Service

-

WarrantyOne Year

-

HS Code6802919000

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE; ISO

-

Minimum Order Quantity1

-

Delivery Time7-15Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

Rubber Connection Hard Marble Stone Diamond Wire Saw For Granite

High-Quality Stone Diamond Wire Saw for Granite

Description of Beaded Diamond Wire Saw

The selection of diamond beaded rope is related to the type, hardness, and other factors of the material to be cut. The best cutting effect and longest service life can be achieved by selecting the beaded rope properly. According to the type of cutting, the cutting of beaded rope is divided into mining cutting, shaping Cutting, plate processing cutting and special-shaped product processing cutting, and other types.

According to the type of equipment used, beaded ropes can be divided into beaded ropes for mobile wire saw machines for mining, beaded ropes for stationary wire saw machines for shaping and plate cutting, beaded ropes for special-shaped processing, Beaded ropes for multi-wire saw machines for panel cutting and beaded ropes for concrete demolition cutting.

Technical Parameters of Beaded Diamond Wire Saw

| Diamond wire saw for concrete | |||||||

| Product Model | Bead Specification | Number of beads | Connection | Cutting Materials | Line Speed (m/s) | Cutting Speed m3/h) | wire life (m3/m) |

| GD-11 | Ø11.5 | 40 | Rubber+Spring | High-strength reinforced concrete | 22-25 | 1-3 | 2-4 |

| GD-12 | Ø11.5 | 40 | Rubber+Spring | Underwater reinforced concrete | 20-23 | 1-2 | 2-3 |

| GD-13 | Ø11.5 | 40 | Rubber+Spring | Steelworks or structures made of other metals | 19-21 | 0.8-1.5 | 0.8-2 |

| Diamond wire saw for Granite | |||||||

| Product Model | Bead Specification | Number of beads | Connection | Cutting Materials | Line Speed (m/s) | Cutting Speed m3/h) | wire life (m3/m) |

| GD-21 | Ø11.5 | 40 | Rubber | Hard Granite | 26-35 | 5-8 | 8-18 |

| GD-22 | Ø11.5 | 40 | Rubber | Medium-hard granite | 30-40 | 8-18 | 18-25 |

| GD-23 | Ø11.5 | 40 | Rubber | Soft granite | 35-45 | 18-25 | 28-45 |

| Diamond wire saw for | |||||||

| Product Model | Bead Specification | Number of beads | Connection | Cutting Materials | Line Speed (m/s) | Cutting Speed m3/h) | wire life (m3/m) |

| GD-31 | Ø11.5 | 40 | Rubber | Hard Granite | 30-35 | 8-15 | 25-35 |

| GD-32 | Ø11.5 | 40 | Rubber | Medium-hard granite | 35-38 | 10-18 | 40-80 |

| GD-33 | Ø11.5 | 40 | Rubber | Soft granite | 35-42 | 18-25 | 100-150 |

![]()

Beaded Diamond Wire Saw Features

1. Marble, limestone, limestone, and other softer stones are suitable for spring and sintered or electroplated beaded fixed wire saws. For granite, Gabbro, and other hard stones, we use injection molding between beads or rubber injection. If it is used for more demanding cutting (such as cutting concrete), springs are usually added between the beads and then injection molding or rubber injection molding is performed.

2. Granite mining: mainly suitable for rubber and injection-molded wire saws, it can protect the internal wire rope well and increase the tensile strength of the wire saw.

3. Marble mining: Three types of wire saws can be used: spring, injection, and rubber.

3. Diamond combination wire saw: widely used in cutting all kinds of granite slabs.

4. Reinforced concrete cutting wire saw: widely used in the field of construction, can cut houses, bridges, large piers, cement pipes, and underwater buildings.

![]()

Advantages of Beaded Diamond Wire Saw

1. The diamond wire quarrying technique can highly improve the quarrying efficiency, reduce the waste of mining resources,

2. It can exploit large-dimension blocks. At the same time, it can be operated safely and it is good for environmental protection.

3. Independently developed the special rubber and vulcanized technique to ensure that the diamond wires can work in all sorts of bad environments.

4. The rubber and cable sticking together tightly make good bonding, and this can be more strikes during the work.

5. The vulcanized rubber easily withstands increases in temperature caused by badly controlled water spraying, which often happens in a quarry.

Entire Service

We would provide customers with a one-year warranty, during processing, if customers have any problems with installation and use, we have professionals to provide online text, voice, or video communication services for them.