-

Highlight

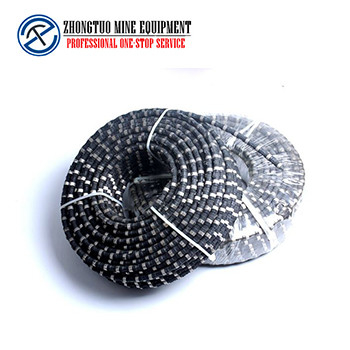

Black Classical Diamond Wire Saw

,Various rock Diamond Wire Saw

,Mine Granite Diamond Cutting Rope

-

ColorBlack

-

StyleClassical

-

ApplicationVarious Rock Materials

-

MaterialDiamond Bead

-

HS Code6802919000

-

Transport PackageWooden Case

-

After-sales ServiceTracking Guidance & Service

-

WarrantyOne Year

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE; ISO

-

Minimum Order Quantity1

-

Delivery Time7-15Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

Black Classical Diamond Wire Saw Mine Granite Diamond Cutting Rope

High-quality Diamond Wire Saw Wire Rope Diamond for Mine Granite Cutting

Description of Beaded Diamond Wire Saw

The selection of diamond beaded rope is related to the type, hardness, and other factors of the material to be cut. The best cutting effect and longest service life can be achieved by selecting the beaded rope properly. According to the type of cutting, the cutting of beaded rope is divided into mining cutting, shaping Cutting, plate processing cutting and special-shaped product processing cutting, and other types.

According to the type of equipment used, beaded ropes can be divided into beaded ropes for mobile wire saw machines for mining, beaded ropes for stationary wire saw machines for shaping and plate cutting, beaded ropes for special-shaped processing, Beaded ropes for multi-wire saw machines for panel cutting and beaded ropes for concrete demolition cutting.

Technical Parameters of Beaded Diamond Wire Saw

| Diamond wire saw for concrete | |||||||

| Product Model | Bead Specification | Number of beads | Connection | Cutting Materials | Line Speed (m/s) | Cutting Speed m3/h) | wire life (m3/m) |

| GD-11 | Ø11.5 | 40 | Rubber+Spring | High-strength reinforced concrete | 22-25 | 1-3 | 2-4 |

| GD-12 | Ø11.5 | 40 | Rubber+Spring | Underwater reinforced concrete | 20-23 | 1-2 | 2-3 |

| GD-13 | Ø11.5 | 40 | Rubber+Spring | Steelworks or structures made of other metals | 19-21 | 0.8-1.5 | 0.8-2 |

| Diamond wire saw for Granite | |||||||

| Product Model | Bead Specification | Number of beads | Connection | Cutting Materials | Line Speed (m/s) | Cutting Speed m3/h) | wire life (m3/m) |

| GD-21 | Ø11.5 | 40 | Rubber | Hard Granite | 26-35 | 5-8 | 8-18 |

| GD-22 | Ø11.5 | 40 | Rubber | Medium-hard granite | 30-40 | 8-18 | 18-25 |

| GD-23 | Ø11.5 | 40 | Rubber | Soft granite | 35-45 | 18-25 | 28-45 |

| Diamond wire saw for | |||||||

| Product Model | Bead Specification | Number of beads | Connection | Cutting Materials | Line Speed (m/s) | Cutting Speed m3/h) | wire life (m3/m) |

| GD-31 | Ø11.5 | 40 | Rubber | Hard Granite | 30-35 | 8-15 | 25-35 |

| GD-32 | Ø11.5 | 40 | Rubber | Medium-hard granite | 35-38 | 10-18 | 40-80 |

| GD-33 | Ø11.5 | 40 | Rubber | Soft granite | 35-42 | 18-25 | 100-150 |

![]()

Beaded Diamond Wire Saw Features

1. Marble, limestone, limestone, and other softer stones are suitable for spring and sintered or electroplated beaded fixed wire saws. For granite, Gabbro, and other hard stones, we use injection molding between beads or rubber injection. If it is used for more demanding cutting (such as cutting concrete), springs are usually added between the beads and then injection molding or rubber injection molding is performed.

2. Granite mining: mainly suitable for rubber and injection-molded wire saws, it can protect the internal wire rope well and increase the tensile strength of the wire saw.

3. Marble mining: Three types of wire saws can be used: spring, injection, and rubber.

3. Diamond combination wire saw: widely used in cutting all kinds of granite slabs.

4. Reinforced concrete cutting wire saw: widely used in the field of construction, can cut houses, bridges, large piers, cement pipes, and underwater buildings.

![]()

How to use Diamond Wire Saw for Mining

The first is drilling. drilling is a key preparatory work. If the hole is not well drilled, it will directly affect the penetration of the diamond wire saw and affect the service life and cutting efficiency of the wire saw. Therefore, the process of punching is particularly important. for cutting a large block, it needs to make three holes, one vertical hole, and two horizontal holes.

Secondly, the diamond wire is threaded and perforated. At present, we mostly use the manual method of threading, fixing one end of the rope with a multi-strand loop cord, passing it in from one hole, and using iron wire to lead out from the other hole. In foreign countries, there is a method of animal threading, like the mouse is tied to a wire and filled with water to allow the mouse to drill out of another hole.

Then install the wire saw machine. because the equipment is heavy, and after cutting a flat surface, the equipment needs to be re-adjusted, so it requires lifting equipment around it, which can be lifted at any time. After the equipment is installed, you can start cutting. Generally, the horizontal cutting is performed first, and then the vertical cutting is performed to prevent the wire saw from idling or jamming the beaded rope after the vertical cutting at the final stage of the horizontal cutting process. Must pay attention to the water supply during the cutting process, otherwise, the large amount of heat generated by the cutting will cause the steel wire to deform, or the rubber will age, and the spring will melt and lose the role of fixing the beads, which will shorten the life of the wire saw.

Adjustment, In the process of mining, the bending angle of the wire saw is constantly shrinking. In the last part, the bending angle of the wire saw is very large, so at this time, we must pay attention to the running state of the wire saw. If there are sparks or the sound of the wire saw cutting is too large, it is best to find a good location and add a flywheel, so as to keep the wire saw from over-bending and causing deformation, thereby shortening the service life.