-

Highlight

600t Lifting Jack Machine

,60t Lifting Jack Machine

,Synchronous Lifting System Equipment

-

Cylinder Stroke Mm500

-

CertificationCE, ISO

-

Working Pressure MPa31.5

-

SpecificationCustomized

-

Jack Weight148-8520

-

OriginChina Shaanxi

-

After-sales ServiceTracking Guidance & Service

-

WarrantyOne Year

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE; ISO

-

Minimum Order Quantity1

-

Delivery Time7-15Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

60-600t Lifting Jack Machine Synchronous Lifting System Equipment

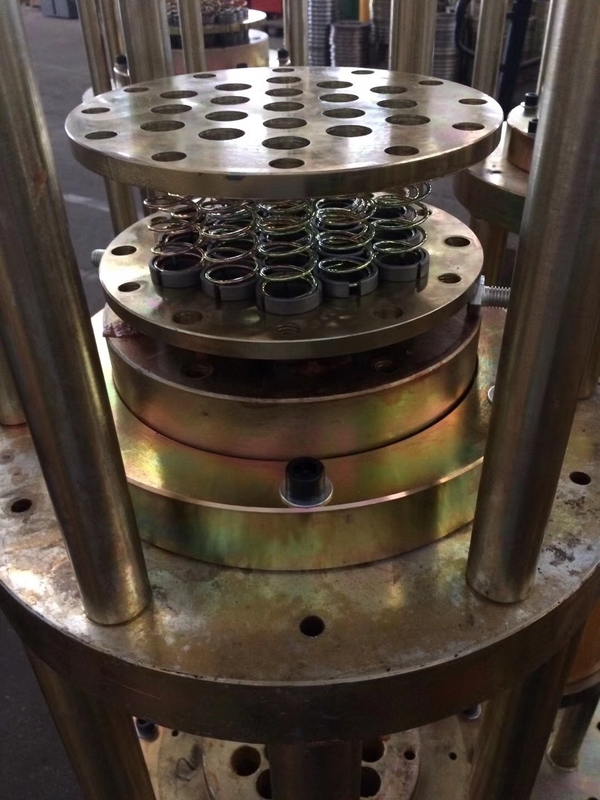

60-600t Synchronous Lifting System Equipment Synchronous Lifting System Jack

Introduction of Synchronous lifting jack

Synchronous lifting jack is a new type of large-scale component lifting equipment, which is mainly composed of a lifting jack, hydraulic pump station, and control system. The principle is to integrate the prestressed anchorage technology with the hydraulic jack technology, anchor the steel strand through the anchorage, and then use the computer to centrally control the flow and oil pressure output by the hydraulic pump station, drive the piston of the lifting jack to extend and retract, and drive the steel wire. The stranded wire and components are lifted and lowered to achieve the overall synchronous lifting and lowering of large components.

Technical Parameter of Synchronous lifting jack

| model | Safe working load |

Working pressure MPA |

Cylinder stroke mm |

Retraction height mm |

Jack weight KG |

Fixed anchor weight KG |

boost speed m/h |

Number of strands | Strand diameter |

| ZT-TSD15 | 15 | 31.5 | 500 | 1846 | 148 | 3.2 | 0-25 | 1 | 18 |

| ZT-TSD45 | 45 | 31.5 | 500 | 1726 | 600 | 28 | 0-25 | 3 | 18 |

| ZT-TSD60 | 60 | 31.5 | 500 | 1726 | 630 | 32 | 0-25 | 4 | 18 |

| ZT-TSD100 | 100 | 31.5 | 500 | 1790 | 930 | 46 | 70-25 | 7 | 18 |

| ZT-TSD180 | 180 | 31.5 | 500 | 1886 | 1560 | 90 | 0-25 | 12 | 18 |

| ZT-TSD280 | 280 | 31.5 | 500 | 1938 | 2330 | 130 | 0-25 | 19 | 18 |

| ZT-TSD300 | 300 | 31.5 | 500 | 1940 | 2460 | 140 | 0-25 | 20 | 18 |

| ZT-TSD400 | 400 | 31.5 | 500 | 2100 | 3396 | 220 | 0-25 | 27 | 18 |

| ZT-TSD580 | 580 | 31.5 | 500 | 2220 | 4980 | 260 | 0-25 | 38 | 18 |

| ZT-TSD680 | 680 | 31.5 | 500 | 2180 | 5410 | 320 | 0-25 | 45 | 18 |

| ZT-TSD800 | 800 | 31.5 | 500 | 2200 | 6880 | 360 | 0-25 | 54 | 18 |

| ZT-TSD1000 | 1000 | 31.5 | 500 | 2286 | 8520 | 560 | 0-25 | 66 | 18 |

Working Principle Synchronous Lifting System Jack

The Lifting Hydraulic Strand Jack working principle is to integrate the prestressed anchor anchoring technology with the hydraulic jack technology, anchor the steel strand through the anchor, and then use the computer to centrally control the flow and oil pressure output of the hydraulic pump station. The device drives the jack piston to extend and contract (displacement sensor device)and forces the steel strand and the component to rise, descend, and continuously translate to realize the overall synchronous lifting (translation) and lowering movement.

![]()

Applicable fields of Synchronous lifting jack

This technology is suitable for the steel tower mast of the antenna and the gym, swimming pool, hangar, theatres, waiting room (the ship), and other large utility of network frame, roof and steel bridge structures, and large gantry crane girder of the ascent of the whole as well as the main building of the airport terminal of the ascent of the whole steel roof truss (cover) slip.

Synchronous of lifting jack features

lifting equipment small volume, light dead weight, large bearing capacity, convenient and flexible installation, especially suitable for small space or indoor large tonnage component lifting; By lifting equipment to expand the combination, lifting weight, span, the area is not limited; Using low relaxation steel strand, as long as there is a reasonable bearing point, lifting height is not limited; The lifting jack anchor has reverse motion self-locking property so that the lifting process is very safe, and the members can be reliably locked at any position in the lifting process for a long time; The equipment has a high degree of automation, convenient and flexible operation, with automatic operation, semi-automatic operation, single point adjustment, manual operation, and other operation modes. LCD display and touch screen display are very intuitive. And the control system is equipped with a self-error correction protection program, even so, that the misoperation will not cause safety accidents. With this equipment construction, the construction period is short, low cost, good economic benefits.

![]()

![]()

Bridge tensioning equipment is our primary research and development project, from R & D to manufacturing and installation, we strictly control every link to provide customers with high-quality products and active after-sales service.

Late autumn yellow, can also be customized according to personal preferences. Note: The specific color of the actual production batches shall prevail! The wooden package can also be customized according to individual needs packaging.