Economical and practical cement brick making machine, small burn-free hollow brick machine

-

Highlight

Economical Cement Brick Making Machine

,Small Cement Brick Making Machine

,Practical Cement Brick Making Machine

-

TypeBrick Machine

-

Vibration Frequency50 HZ

-

Molding Cycle30 S

-

Working Pressure200Mpa

-

Total Weight900KG

-

Molding Pressure300Ton

-

Size150*100*170 Cm

-

Place of Originchina

-

Brand NameZT

-

CertificationCE

-

Model NumberZTFBX- 705

-

Minimum Order Quantity1

-

Price700-1350

-

Packaging Detailswooden packaging

-

Delivery Time1-3 Day

-

Supply Ability10 pcs/day

Economical and practical cement brick making machine, small burn-free hollow brick machine

Economical and practical cement brick making machine, fixed solid cement block brick making machine, small burn-free hollow brick making machine

product description

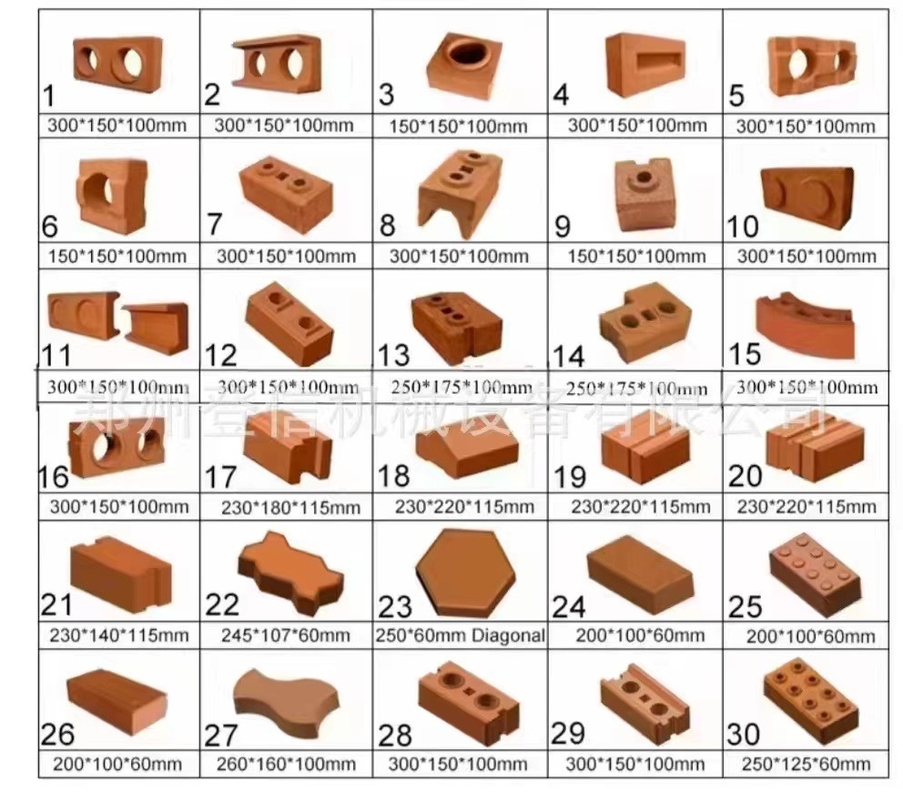

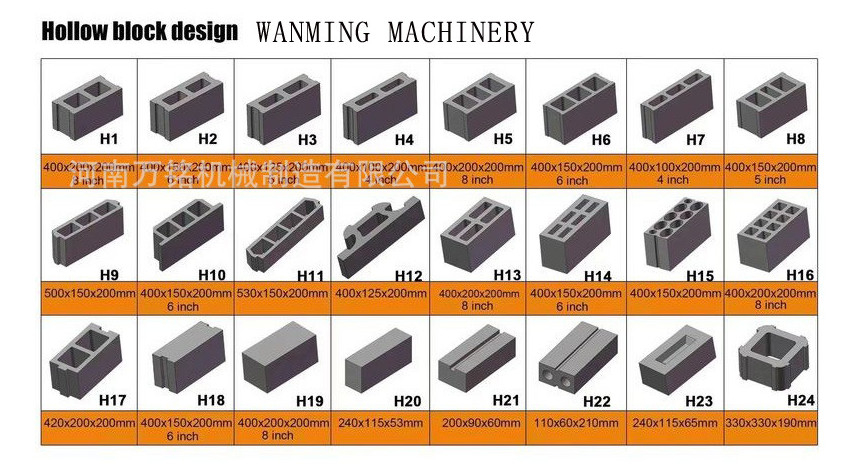

This machine can use river sand, gravel, slag, slag, expanded perlite, fly ash, ceramsite, etc. as the main raw materials, add an appropriate amount of cement, and use different proportions to produce standard and non-standard blocks. Lots, load-bearing blocks, non-load-bearing blocks and lightweight blocks. The surface of the blocks is complete, dense and beautiful.

This machine is easy to operate and can replace various molds to produce hollow bricks and standard bricks of various specifications. It is a good machine for rural areas to get rich. It uses agricultural electric power and does not require pallets. It can produce two to eight blocks at a time. One person can produce on the road.

Instructions:

1. Check whether all parts of the machine are loose; lubricating oil should be added to the oil injection part to reduce mechanical friction and extend service life.

2. After turning on the power, press the mold lifting button and hang the indenter; overlap the mold box and the indenter several times to check whether it is smooth.

3. Press the mold lowering button, drop the mold box onto the wooden pallet, push the pressure head back, and start adding materials into the mold box, then turn on the vibration button and vibrate for 5-8 seconds, stop vibrating and add a little material. The material is scraped to the horizontal position of the mold box.

4. Pull back the pressure head and hit the stopper. The hook under the plate will drop the pressure head. At the same time, turn on the upper vibration and lower vibration switches. When the horizontal bars on the two halves of the screw reach the position, turn off the up and down vibration buttons. Start the rising button and hang the upper pressure head on the hook. It must stop immediately when it reaches the position to avoid collision. Only after the hook is firmly hung can the bricks and pallets be pulled out with a forklift.

Structural principles and characteristics

1. The cement brick making machine adopts four-column guide and is equipped with a strong vibration motor. It uses a vibration table for directional vertical vibration and upper mold pressure vibration to achieve a strong vibration effect with a small power, so that each raw material can be effectively processed. The dense flow filling greatly improves the production efficiency, and the produced blocks have uniform density and high strength.

2. This machine uses upper mold push-pull and manual scraping to produce bricks. The operation is convenient and flexible, and you can quickly become familiar with it.

3. The machine body is made of large-scale steel and special welding technology and materials, which is strong and shock-resistant. The suspension and connection parts of the whole machine adopt "spring isolation technology" and directional vertical vibration technology, which reduces power loss, improves density, and achieves good performance. The shock-absorbing effect also reduces the wear of the mold and prolongs the working life of the mold.

4. The wooden pallet resonates synchronously with the mold during molding and is not affected by impact. The wooden pallet has a long service life.

5. One machine has multiple functions. It is equipped with different specifications of molds and can produce cement bricks of different specifications. The molds are easy to replace and easy to maintain.

6. The press head can be moved longitudinally, which is convenient for feeding, maintenance and flushing. The gap between the presser foot and the mold box is small, the burrs of the blocks are small, and the appearance is good.

Product display

![]()

![]()

![]()

![]()

![]()

![]()

![]()