Low Relaxation Non Cohesive Stranded Steel Wire For Bridge Construction

-

Highlight

Non Cohesive Stranded Steel Wire

,Low Relaxation Stranded Steel Wire

,Bridge Construction Low Relaxation Strand

-

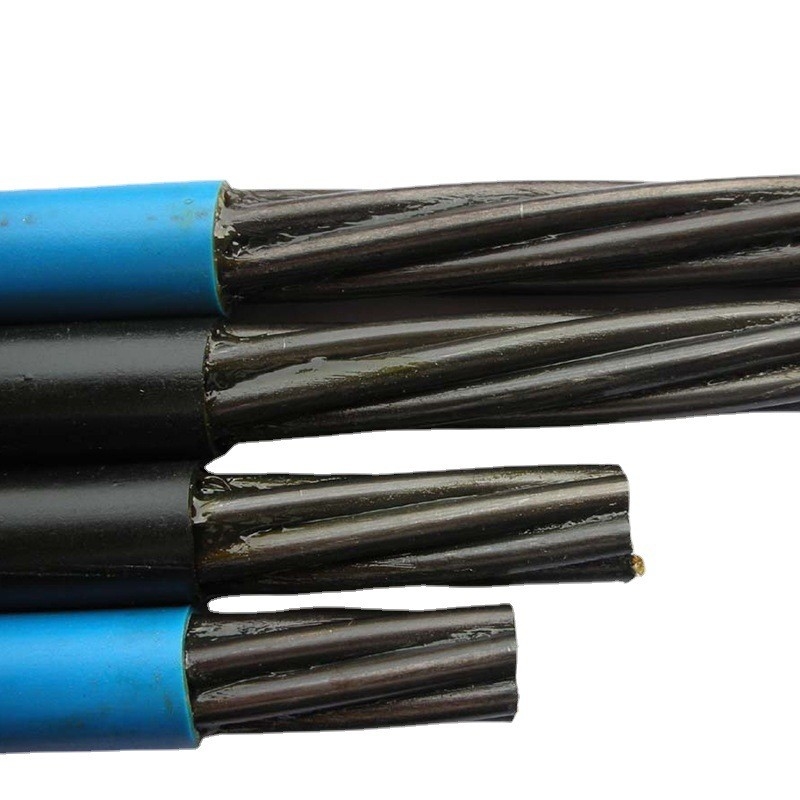

Transport PackagePlastic Film In Blue Color

-

HS Code73121000

-

Strands7 Strands / 9 Strands / 13 Strands

-

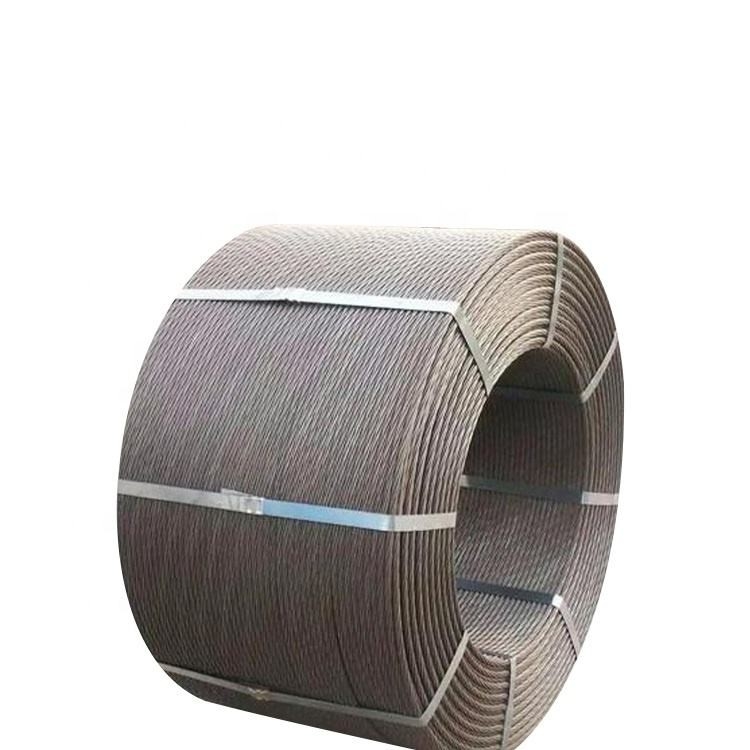

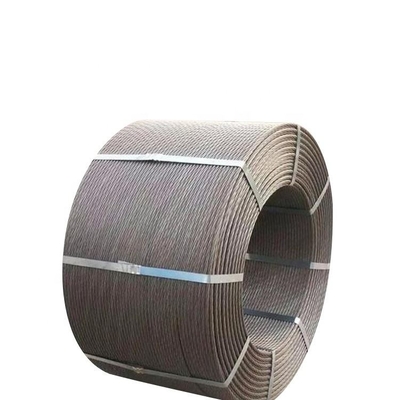

Coil Weight2.4mts-3.2mts

-

RelaxationLow Relaxation

-

ThicknessMetal Thick Wire

-

After-sales ServiceTracking Guidance & Service

-

WarrantyOne Year

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE ISO

-

Minimum Order Quantity1

-

Packaging DetailsWooden Pallet

-

Delivery Time7-15 Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

Low Relaxation Non Cohesive Stranded Steel Wire For Bridge Construction

Non-cohesive Steel Strand for Bridge Construction

Definition of The PC Strands

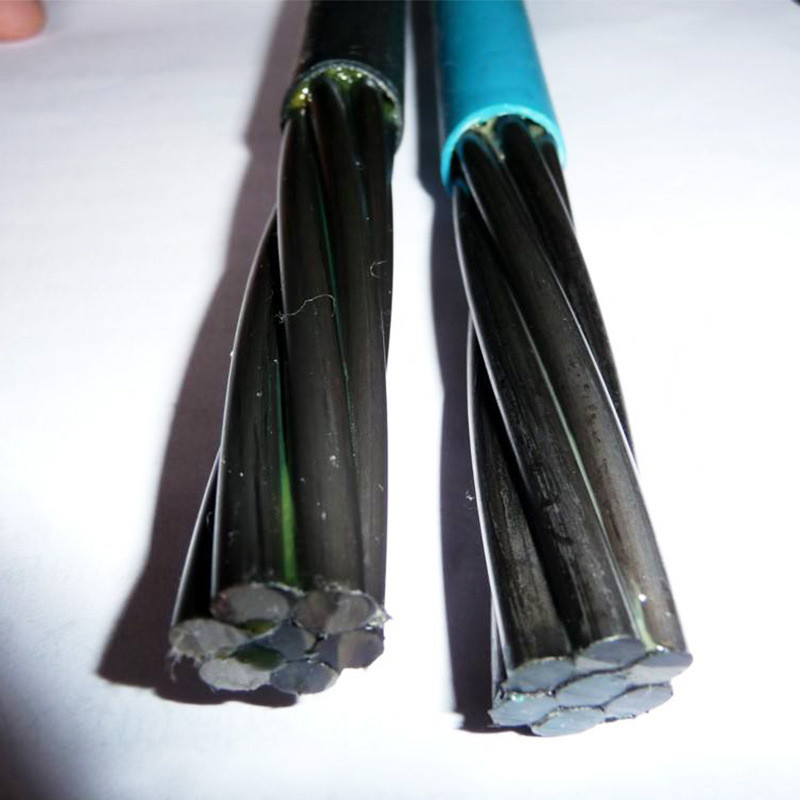

The common interpretation is to apply a layer of grease and plastic sheath on the steel strand (which can be called bare wire). Steel strands and concrete are isolated from each other and can be freely loosened and remain unbonded with concrete, so they are called unbonded steel strands. There are also galvanized unbonded steel strands used for reinforcement projects, that is, galvanized steel strands are coated with grease and plastic sheaths to double guarantee the anti-corrosion results.

Technical Parameter of The PC Strands

| Dia(mm) | Tensile Strength(Rm/MPa) | Max strength for hole wire(Fm/kN) | StipulatedNominal Non proportional extension rate(Fp0.2/kN) | Cross section size(mm2) | Approximate weight(g/m) | Tolerance(mm) |

| 12.7 | ≥1860 | ≥185.1 | ≥166 | 98.7 | 775 | +0.4~-0.2 |

| 15.2 | ≥1860 | ≥262.5 | ≥235 | 150 | 1178 | +0.4~-0.2 |

| 12.8 | ≥1860 | ≥358 | ≥318 | 191 | 1500 | +0.4~-0.2 |

![]()

![]()

Production Process of Non-cohesive Steel Strand

The production process of unbonded prestressed steel strand is as follows: steel strand setting out → anti-corrosion smooth grease coating → plastic wrapping machine wrapped with polyethylene sheath → water cooling → traction → wire taking up → packaging. First, the anti-corrosion smooth grease is evenly coated on the surface of the steel strand through the coating equipment, and the routing speed of the steel strand and the operating parameters of the coating equipment is adjusted to make the steel strand form a uniform anti-corrosion smooth coating; Then, the polyethylene is extruded into tubes through the extruder and tightly wrapped on the steel strand coated with anti-corrosion smooth coating; Finally, the steel strand after the plastic coating is cooled to normal temperature through the cooling water tank, so that the polyethylene sheath can be rapidly cooled and hardened, then the wire is taken in, and the whole production process is completed after packaging.

![]()

Application of Non-cohesive Steel Strands

It is mainly used for civil construction projects with large static loads, large-span workshops, or high-rise buildings. Advantages: The construction speed is fast, the thickness of the beam plate is reduced, and the structural performance and economic effect are increased.

In bridge construction and prestressed construction of large-span garages, due to the large dynamic load, bonded steel strands are necessary for the design, that is, ordinary steel strands. Because the construction grouting is directly bonded to the concrete, it produces a strong gripping force. It is not as difficult to anchor both ends as in the construction of unbonded steel strands, so the safety factor is enhanced.

The difference between the use of unbonded steel strands and bonded steel strands

The unbonded steel strand is mainly used in the post-tensioning prestressing system. The difference from the bonded steel strand is that the prestress is not bonded to the surrounding concrete; during its operation, the permanent allowable prestress is longitudinally opposed to the surrounding concrete. slide. The prestress is completely transferred to the concrete by the anchorage.