-

Highlight

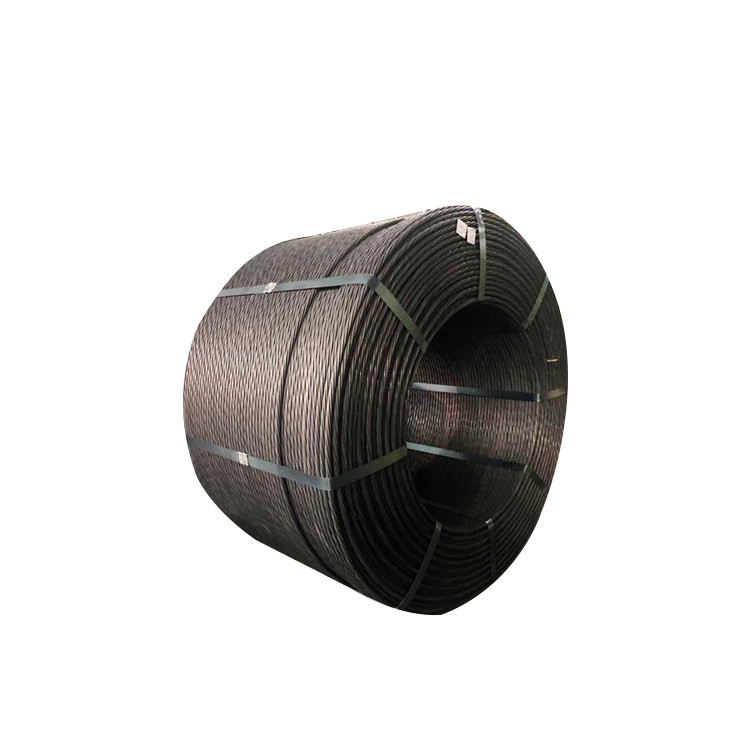

High Strength Low Relaxation PC Strand

,Low Relaxation PC Strand 1860MPa

,1860MPa PC Steel Wire

-

Transport PackagePlastic Film In Blue Color

-

HS Code73121000

-

Strands7 Strands / 9 Strands / 13 Strands

-

Coil Weight2.4mts-3.2mts

-

RelaxationLow Relaxation

-

ThicknessMetal Thick Wire

-

After-sales ServiceTracking Guidance & Service

-

WarrantyOne Year

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE ISO

-

Minimum Order Quantity1

-

Packaging DetailsWooden Pallet

-

Delivery Time7-15 Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

High Strength Low Relaxation PC Strand 1860MPa PC Steel Wire

Description of Prestressing Post-Tensioned PC Strand

Steel strands are steel products made up of multiple stranded steel wires. The surface of carbon steel can be added with galvanized layer, zinc-aluminum alloy layer, aluminum cladding, copper cladding, and epoxy coating as required.

The manufacturing process is divided into monofilament manufacturing and strand manufacturing. Monofilaments are produced by (cold) drawing technology. Depending on the material of the product, it can be a high carbon steel wire rod, stainless steel wire rod, or medium and low carbon steel wire rod. If galvanizing is required, the monofilament should be electroplated or hot-dip galvanized. In the manufacturing process of steel strands, multiple steel wires are twisted into products through a stranding machine, and the prestressed steel strands need to be continuously stabilized after being formed. The products are generally collected on the I-shaped wheel or the finished product is a shaftless roll.

Technical Parameter of Prestressing Post-Tensioned PC Strand

| Dia(mm) | Tensile Strength(Rm/MPa) | Max strength for hole wire(Fm/kN) | StipulatedNominal Non proportional extension rate(Fp0.2/kN) | Cross section size(mm2) | Approximate weight(g/m) | Tolerance(mm) |

| 12.7 | ≥1860 | ≥185.1 | ≥166 | 98.7 | 775 | +0.4~-0.2 |

| 15.2 | ≥1860 | ≥262.5 | ≥235 | 150 | 1178 | +0.4~-0.2 |

| 12.8 | ≥1860 | ≥358 | ≥318 | 191 | 1500 | +0.4~-0.2 |

![]()

Features of Post-Tensioned PC Strands

Stranded steel cable composed of multiple high-strength steel wires and treated with stress relief (stabilization treatment), suitable for prestressed concrete or similar applications, with saving steel, high tensile strength, good elongation, low relaxation, stress With the characteristics of small loss and excellent fatigue resistance, it is a product with high technical content and good quality among high-efficiency steel products. PC steel strands are widely used in highways, bridges, sleepers, large stadiums, high-rise buildings, airports, ports, wharves, nuclear power plants, dams, urban elevated and light rail, and other infrastructure construction fields.

![]()

Application of High Tension Strands Steel Wire Galvanized

1) Used in the upper plates of bridges

2) As cable for special bridges and for the maintenance of bridges

3) In construction, this product is used in concrete pillars and supports for the construction of buildings, domes for nuclear

power plants and reinforcement of LNG concrete tanks.

4) It is also used as floor and roof reinforcement for sports stadiums.

5) It can be extensively used in construction materials for PC panels, high-pressure concrete water pipes, marine structures,

towers and runways.

Why choose Galvanized Steel Strand

The surface coating of prestressed steel strands with zinc is a useful method of delaying steel wire corrosion and stress corrosion. When the surface of the prestressed steel strand has the defect of reaching the steel base or there are some corrosion pits, the galvanized steel wire will have a hydrogen embrittlement cracking phenomenon. Because the prestressed steel wire has high strength and low plasticity, it is more susceptible to corrosion than ordinary steel bars. If it is exposed to rain, moisture, or corrosive medium during storage and transportation, the prestressed steel will undergo electrochemical corrosion, causing the surface of the steel wire to form corrosion pits of different sizes and distribution, and the corrosion pit is equivalent to a "gap". During the tension process, the stress strands are unevenly distributed, and the stress is concentrated at the edge of the "notch". When the uniform stress is low, the "notch" edge stress has reached the fracture stress, resulting in early cracking. The "notch" active effect caused by corrosion is related to the arrangement of the steel. When there is a higher carbon content and higher residual stress, the "notch" will be more active to the stress. Because the prestressed steel wire has a small cross-section, high stress and low deformation, it is necessary to guard against corrosion.