-

Highlight

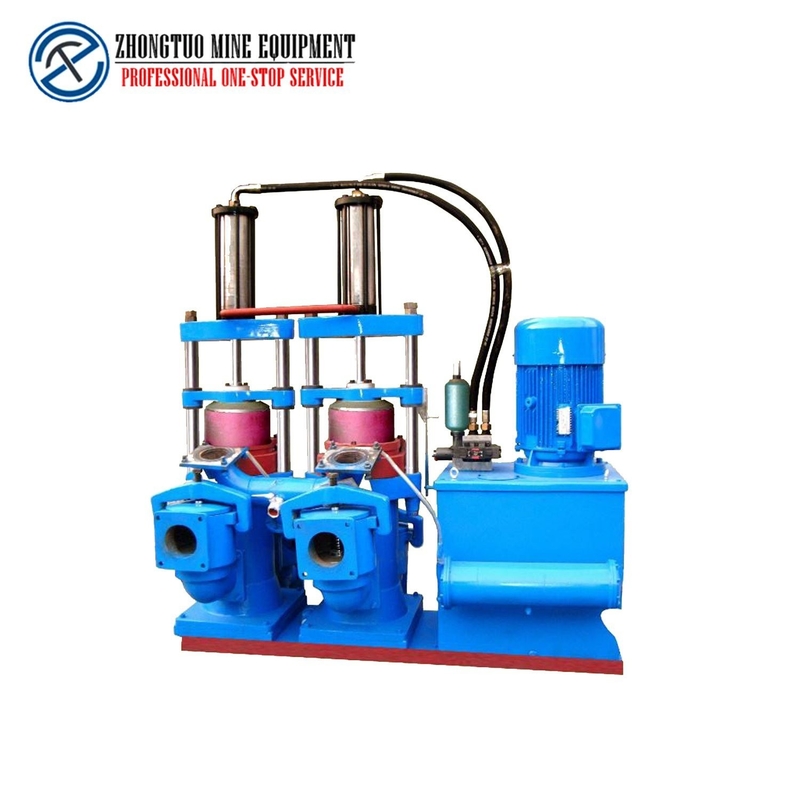

Sewage Treatment Mud Pump Machine

,Double Cylinder Mud Pump Machine

,Hydraulic Mud Pump For Filter Press

-

MaterialsIron, Stainless Steel

-

PowerHydraulic

-

Flow3-120m3/h

-

Pressure0.1-2.5Mpa

-

Inlet Pipe (mm)/(in)58-219mm

-

Stroke200-250mm

-

Weight500-5800kg

-

Transport PackageWooden Case

-

Production Capacity50piecces/Month

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE ISO

-

Minimum Order Quantity1

-

Pricenegotiated

-

Packaging DetailsWooden Carton

-

Delivery Time7-15 Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

Double Cylinder Sewage Treatment Mud Pump Machine For Filter Press

Double Cylinder Sewage Treatment Mud Pump for Filter Press

Description of Double Cylinder Mud Pump

The YB Series plunger pump is a type of positive displacement pump where the high-pressure seal is stationary and a smooth cylindrical plunger slides through the seal. While working, the plungers are driven by a hydraulic system to make a reciprocating motion, thus changing the pump chamber, so that realize the material transportation.

Technical Parameters of Ceramic Mud Pump

| Model | Pressure range(Mpa) | Rated flow(m³/h) | Effective stroke(mm) |

Motor power(kw) | Inlet(mm) | Outlet(mm) | Weight(KG) |

| YB-85 | 0.1-2.5 MPa | 3 | 220 | 4 | 58 | 58 | 550 |

| YB-140 | 0.1-2.5 MPa | 11 | 220 | 11 | 89 | 76 | 950 |

| YB-200 | 0.1-2.5 MPa | 19 | 220 | 18.5 | 108 | 89 | 1250 |

| YB-250 | 0.1-2.5 MPa | 30 | 220 | 22 | 133 | 108 | 1750 |

| YB-300 | 0.1-2.5 MPa | 45 | 220 | 30 | 159 | 133 | 2200 |

| YB-300 (prolonged) |

0.1-2.5 MPa | 60 | 350 | 37 | 159 | 133 | 2850 |

| YB-350 | 0.1-2.5 MPa | 100 | 420 | 55 | 219 | 159 | 5250 |

| YB-400 | 0.1-2.5 MPa | 120 | 420 | 55 | 219 | 219 | 5850 |

| YH-85 | 0.1-2.5 MPa | 3 | 220 | 2.2 | 58 | 58 | 550 |

| YH-140 | 0.1-2.5 MPa | 11 | 220 | 5.5 | 89 | 76 | 950 |

| YH-200 | 0.1-2.5 MPa | 19 | 220 | 7.5 | 108 | 89 | 1250 |

| YH-250 | 0.1-2.5 MPa | 30 | 220 | 11 | 133 | 108 | 1750 |

| YH-300 | 0.1-2.5 MPa | 45 | 220 | 18.5 | 159 | 133 | 2200 |

| YH-300 (prolonged) |

0.1-2.5 MPa | 60 | 350 | 22 | 159 | 133 | 2850 |

| YH-350 | 0.1-2.5 MPa | 100 | 420 | 37 | 219 | 159 | 5250 |

| YH-400 | 0.1-2.5 MPa | 120 | 420 | 37 | 219 | 219 | 5850 |

![]()

Advantages of Ceramic Mud Pump

1. The plunger pump can automatically control the output and can fix the feeding pressure. Once the pressure is set, while the feeding pressure reaches that value, the feeding speed wills vary accordingly and the pressure will maintain.

2. The plunger pump is driven by a hydraulic station, so it can reach higher pressure and works stable.

3. The plunger's material is an aluminum oxide ceramic plunger, and its features are wear-resisting, easy maintenance, cost-saving, and long life span.

4. special plunger pumps can be designed and manufactured according to customer needs.

Application of Ceramic Mud Pump

1. Involved industries: environmental water treatment: municipal sewage, paper sludge, glass polishing, steel rolling, electroplating sewage, rinsing sewage, ceramic stone: leather, and other industries sewage treatment, printing, and dyeing sewage and other industries sewage treatment.

2. Food and pharmaceutical: bean residue powder and other lines of sewage treatment, beer brewing, sugar monosodium glutamate, alcohol, yeast, pharmaceutical sewage, glutinous rice

3. Chemical pigments: oil liquefaction slag, white hair black pigment fuel, titanium dioxide lubricating oil, chemical fiber dilute hydrochloric acid, cosmetics, and other industry's sewage treatment.

![]()

Routine Maintenance of Sewage Treatment Mud Pump

1. Mud pumps and other mechanical equipment should be inspected and maintained on a scheduled and timely basis to find and address problems ahead of time, in order to avoid an unscheduled shutdown.

3. Advanced anti-wear measures should be adopted to increase the service life of the wearing parts, which can reduce the investment cost of the project, and improve production efficiency. At the same time, wearing parts and other mud pump parts should be repaired rather than replaced when possible.

How to Choose a Suitable Mud Pump Type and Model