High Modulus Fiber Glass Geogrid Machine Refinement High Performance

-

Highlight

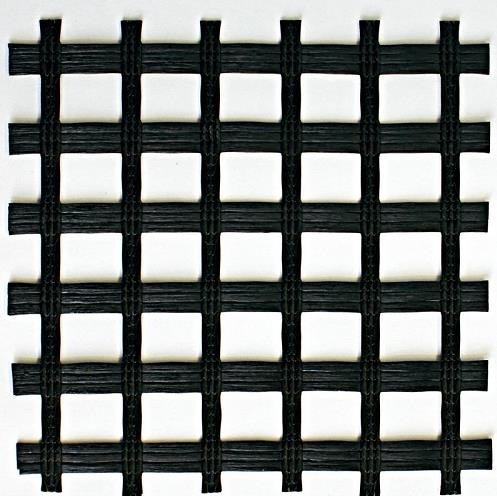

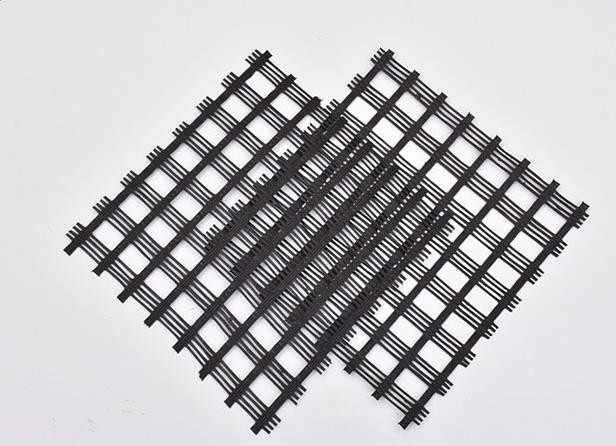

High Modulus Fiber Glass Geogrid

,Fiber Glass Geogrid High Performance

,Fiberglass Geogrid Mesh

-

Portrait Tension Force (kN/m)30-150

-

MaterialFiberglass

-

ConditionNew

-

Transport PackageWooden Box

-

After-sales ServiceTracking Guidance & Servic

-

WarrantyOne Year

-

BrandZHONGTUO

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE; ISO

-

Minimum Order Quantity1PC

-

Packaging DetailsWooden Case

-

Delivery Time7-15Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

High Modulus Fiber Glass Geogrid Machine Refinement High Performance

Glass Fiberglass Geogrid Refinement High-performance

Description of Fiberglass Geogrid

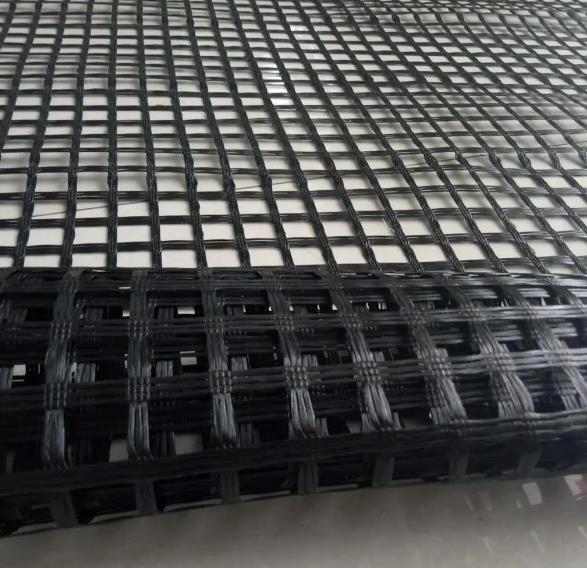

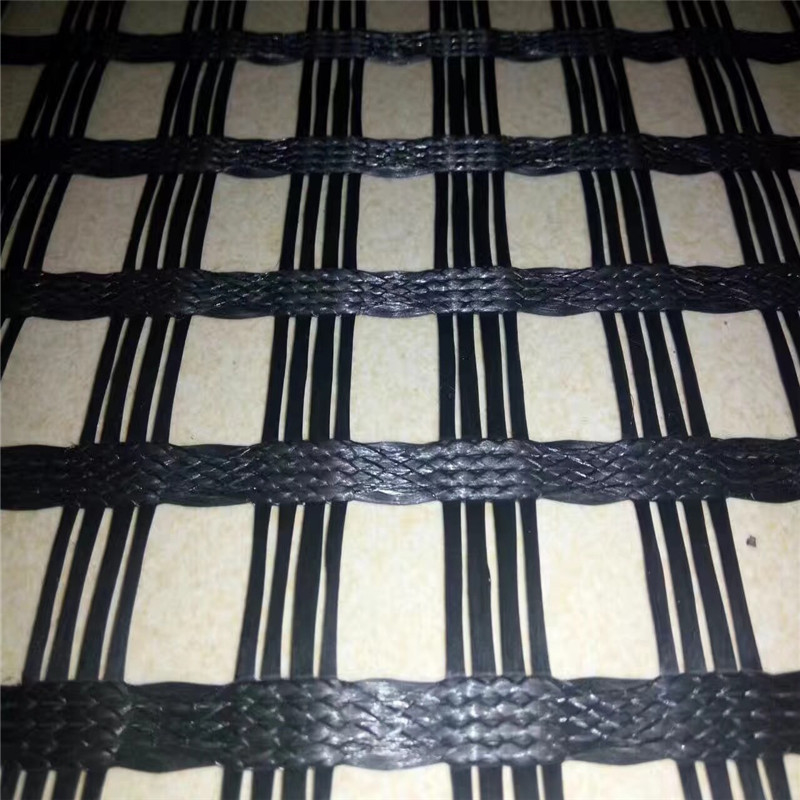

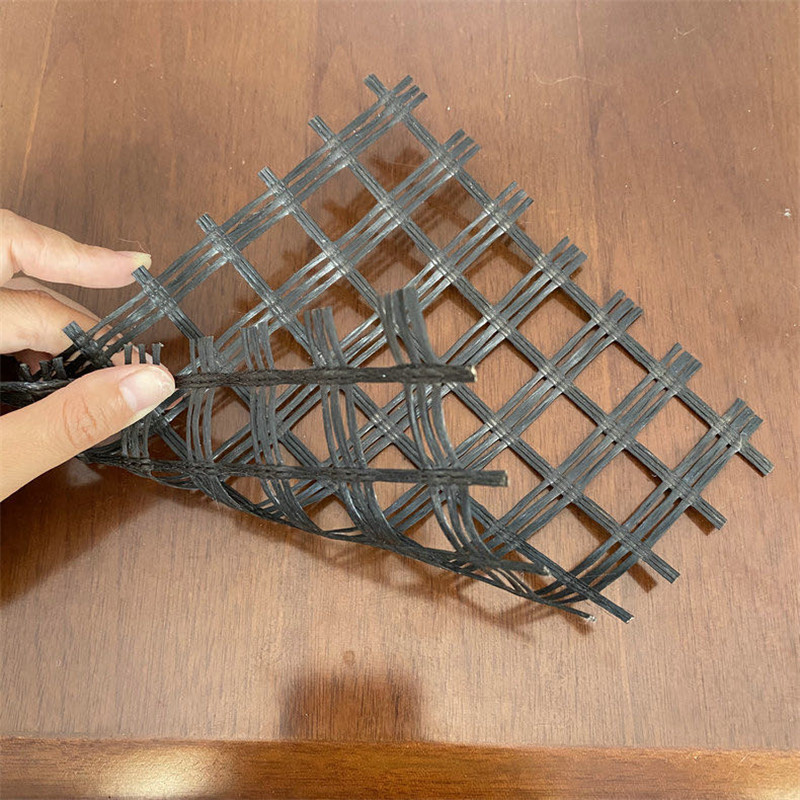

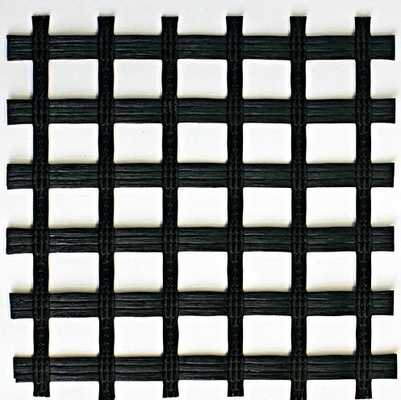

Fiberglass geogrid is made of glass fiber and a mesh structure material made by a certain weaving process. In order to protect the glass fiber and improve the overall performance, it is a geocomposite material made by a special coating process. The main components of glass fiber are silicon oxide, which is an inorganic material. Its physical and chemical properties are extremely stable, and it has high strength, high modulus, high wear resistance and excellent cold resistance, no long-term creep; thermal stability and Good performance; the mesh structure makes the aggregate interlock and limit; improve the load-bearing capacity of the asphalt mixture. Because the surface is coated with special modified asphalt, it has dual composite properties, which greatly improves the wear resistance and shear capacity of the geogrid.

Technical Parameter of Fiberglass Geogrid

| Model | ZT30-30 | ZT50-50 | ZT60-60 | ZT80-80 | ZT100-100 | ZT120-120 | ZT150-150 | |

| Grid size(mm) | 25.4*25.4 or 12.7*12.7 | |||||||

| Breaking strength≥(kN/m) | Radial | 30 | 50 | 60 | 80 | 100 | 120 | 150 |

| Weft | 30 | 50 | 60 | 80 | 100 | 120 | 150 | |

| Elongation at break≤(%) | Radial | 4 | ||||||

| Weft | 4 | |||||||

| temperature resistance(℃) | -100~280 | |||||||

![]()

Features of Fiberglass Geogrid

1. High tensile strength, low elongation - glass fiber geogrid is made of glass fiber, which has a high resistance to deformation, and the elongation at break is less than 3%.

2. No Long-Term Creep - As a reinforcing material, it is extremely important to have the ability to resist deformation under long-term load, i.e. creep resistance, glass fiber does not creep, which ensures that the product can maintain its performance for a long time.

Thermal stability - the melting temperature of glass fiber is above 1000 ℃, which ensures the stability of glass fiber geogrid to withstand heat during paving operations.

3. Compatibility with Asphalt Mixing - The material coated by the glass fiber geogrid in the post-treatment process is designed for the asphalt mixture, each fiber is fully coated and has high compatibility with asphalt, This ensures that the fiberglass geogrid will not be isolated from the asphalt mixture in the asphalt layer, but will be firmly combined.

![]()

Application Fields of Polyester Warp Knitted Geogrid

1. It is suitable for roadbed reinforcement of various roads, railways, and airports.

2. It is suitable for foundation reinforcement of permanent bearings such as large parking lots and wharf freight yards.

3. Suitable for slope protection of railways and highways.

4. Applicable culvert enhancements.

5. It is suitable for the secondary reinforcement of the soil slope reinforced by the one-way tensile geogrid to strengthen the soil slope further and prevent soil erosion.

6. Reinforcement of mines and tunnels.

Entire Service

We would provide customers with a one-year warranty, during processing, if customers have any problems with installation and use, we have professionals to provide online text, voice, or video communication services for them.