1-6mm High Strength Wire Steel Plastic Geogrid Corrosion Resistance

-

Highlight

High Strength Wire Steel Plastic Geogrid

,Steel Plastic Geogrid Corrosion Resistance

,6mm steel plastic geogrid mesh

-

Portrait Tension Force (kN/m)30-150

-

MaterialSteel

-

ConditionNew

-

Transport PackageWooden Box

-

After-sales ServiceTracking Guidance & Servic

-

WarrantyOne Year

-

ColorBlack

-

BrandZHONGTUO

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE; ISO

-

Minimum Order Quantity1PC

-

Packaging DetailsWooden Case

-

Delivery Time7-15Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

1-6mm High Strength Wire Steel Plastic Geogrid Corrosion Resistance

High Strength Wire Steel Plastic Geogrid

Description of Steel Plastic Geogrid

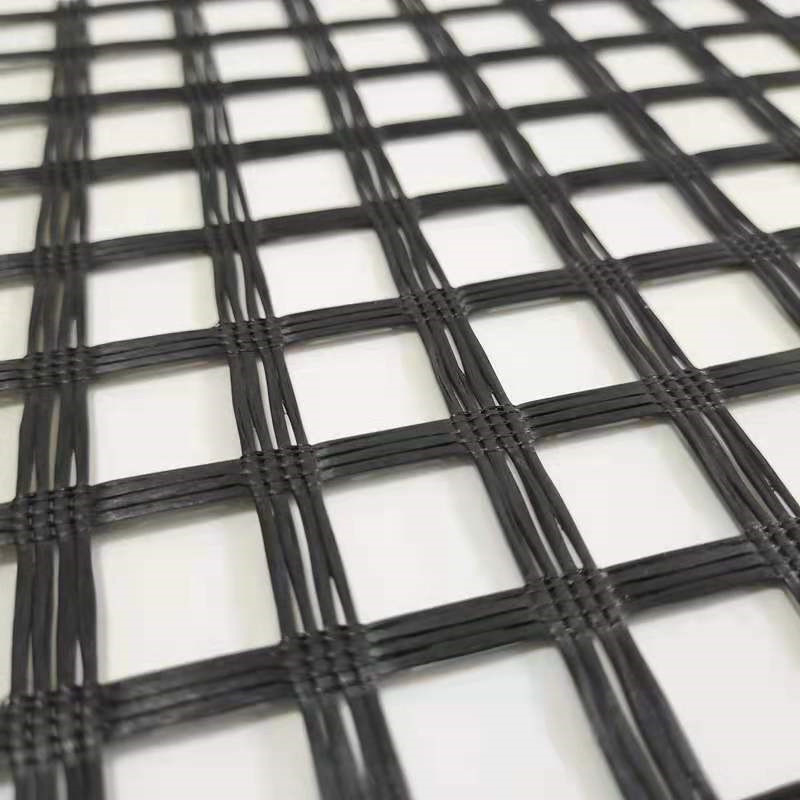

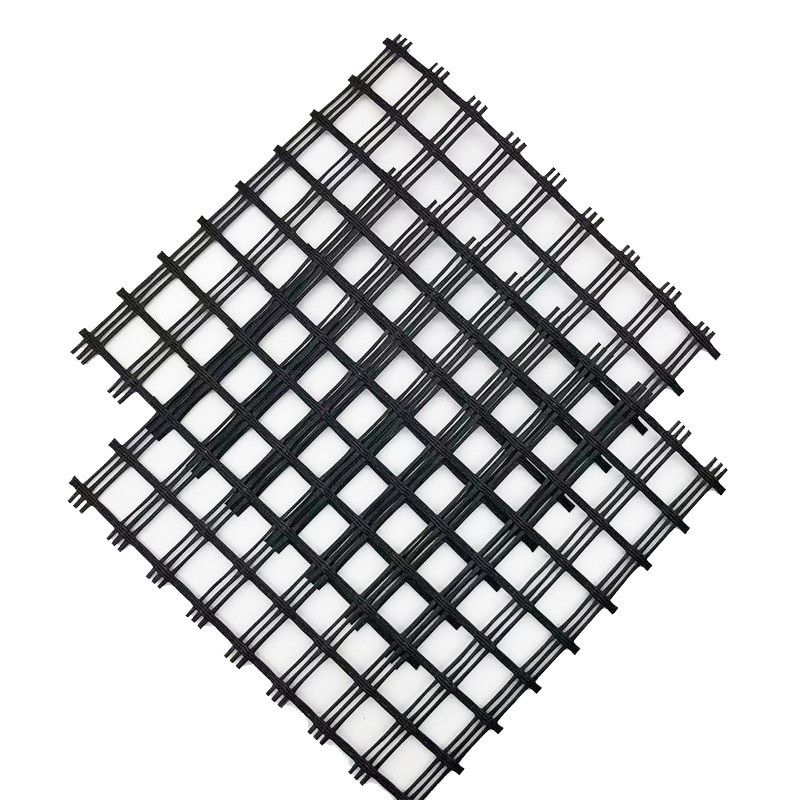

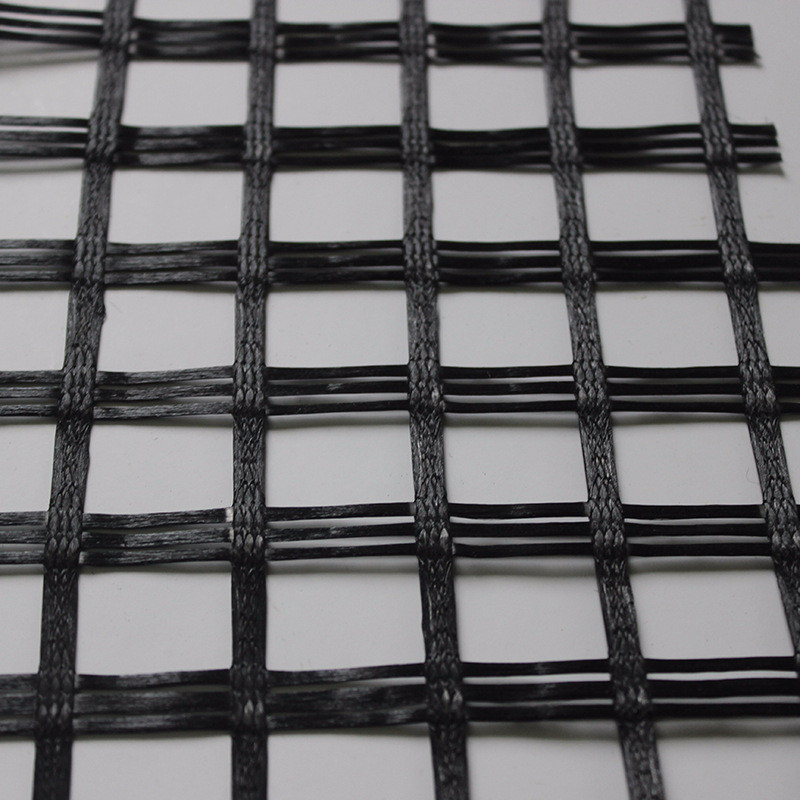

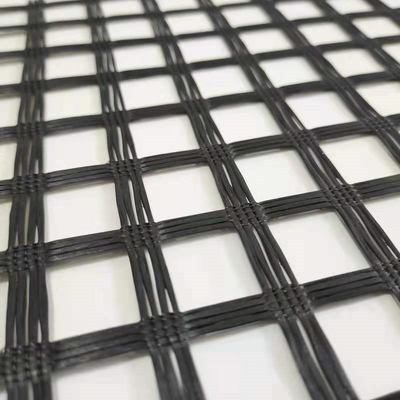

The steel plastic geogrid is made of high-strength steel wire (or other fibers), specially treated, and polyethylene (PE), and other additives are added to make it a composite high-strength tensile strip through extrusion, and the surface has a rough pressure pattern, it is a high-strength reinforced geotextile belt. From this, the single belt is woven or sandwiched at a certain distance vertically and horizontally, and its junction is formed by welding its junction with a special strengthening bonding fusion welding technology, which is a reinforced geogrid.

Technical Parameter of Steel Plastic Geogrid

| Item/Specification | ZT30-30 | ZT40-40 | ZT50-50 | ZT60-60 | ZT80-80 | ZT100-100 | ZT150-150 |

| Portrait Tension Force (kN/m) | 30 | 40 | 50 | 60 | 80 | 100 | 150 |

| Horizontal Tension Force (kN/m) | 30 | 40 | 50 | 60 | 80 | 100 | 150 |

| Tension Rate | 3 | ||||||

| Size(mm) | 1-6 | ||||||

Advantages of Steel Plastic Geogrid

1. High strength and small deformation;

2. Small creep;

3. Corrosion resistance and long service life: The steel plastic geogrid is made of plastic material as a protective layer, supplemented by various additives to make it anti-aging and oxidation resistant, and can resist corrosion in harsh environments such as acid, alkali, and salt. Therefore, steel plastic geogrid can meet the needs of various permanent projects for more than 100 years and has excellent performance and good dimensional stability.

4. The construction is convenient and fast, the cycle is short, and the cost is low: the steel-plastic geogrid is easy to lay, overlap, locate, and level, avoiding overlapping and crossing, which can effectively shorten the project cycle and saving 10%-50% of the project cost.

![]()

![]()

Notices Fields of Polyester Warp Knitted Geogrid

The paving surface of the geogrid should be relatively flat. After the paving layer is qualified, in order to prevent the longitudinal skew phenomenon, first draw a white line or hanging line on the paving layer according to the width, then start the paving, and then use iron Fix the end of the grille with nails (8 nails per meter width, fixed at an even distance), after fixing the end of the grille, use a paving machine to slowly pull the grille forward, and carry out manual labor for every 10 meters long. Tighten and straighten once until one roll of the grille is finished, and then lay the next roll. The operation is the same as before. After laying one roll, use a 6T-10T road roller to roll it from the starting point to the forward direction.