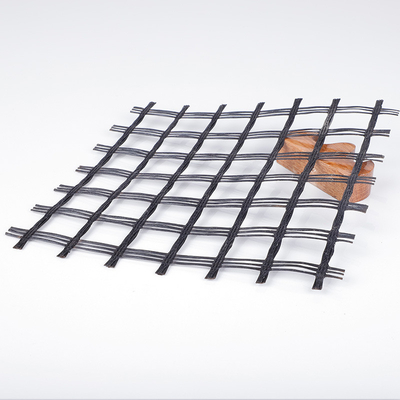

Fiberglass Asphalt Reinforcement Geogrid Machine Mesh High Tensile Strength

-

Highlight

Fiberglass Asphalt Reinforcement Geogrid

,25.4mm Asphalt Reinforcement Geogrid

,High Tensile Strength Geogrid Mesh

-

Portrait Tension Force (kN/m)25-100

-

Tension Rate13-14

-

Size(mm)25.4*25.4

-

MaterialPolyester

-

ConditionNew

-

Transport PackageWooden Box

-

After-sales ServiceTracking Guidance & Servic

-

WarrantyOne Year

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE; ISO

-

Minimum Order Quantity1PC

-

Packaging DetailsWooden Case

-

Delivery Time7-15Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

Fiberglass Asphalt Reinforcement Geogrid Machine Mesh High Tensile Strength

High Tensile Strength Asphalt Reinforcement Fiberglass Geogrid

Description of Fiberglass Geogrid

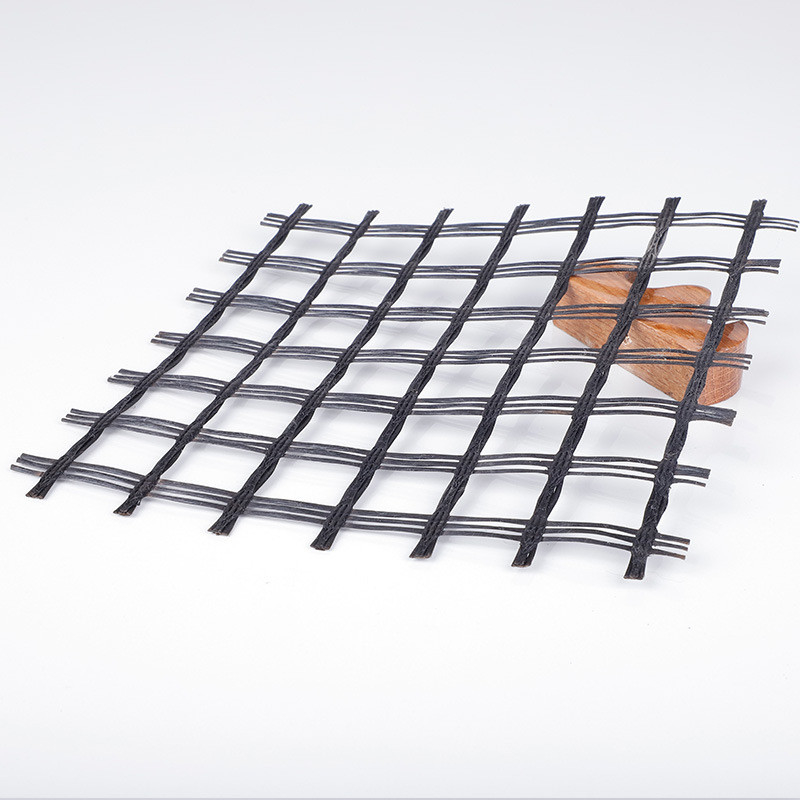

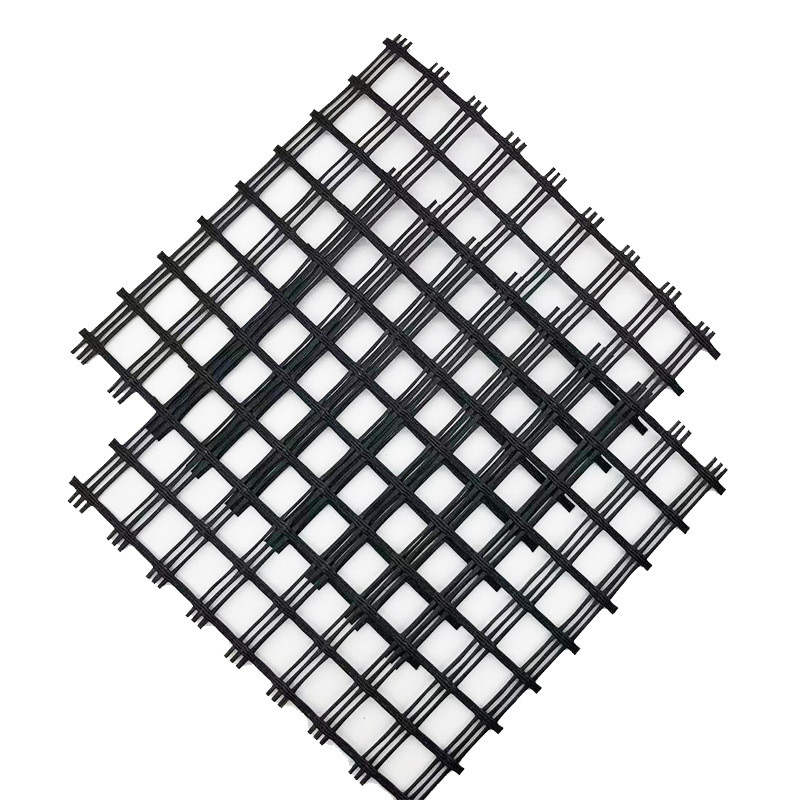

Fiberglass geogrid is made of glass fiber and a mesh structure material made by a certain weaving process. In order to protect the glass fiber and improve the overall performance, it is a geocomposite material made by a special coating process. The main components of glass fiber are silicon oxide, which is an inorganic material. Its physical and chemical properties are extremely stable, and it has high strength, high modulus, high wear resistance and excellent cold resistance, no long-term creep; thermal stability and Good performance; the mesh structure makes the aggregate interlock and limit; improve the load-bearing capacity of the asphalt mixture. Because the surface is coated with special modified asphalt, it has dual composite properties, which greatly improves the wear resistance and shear capacity of the geogrid.

Technical Parameter of Fiberglass Geogrid

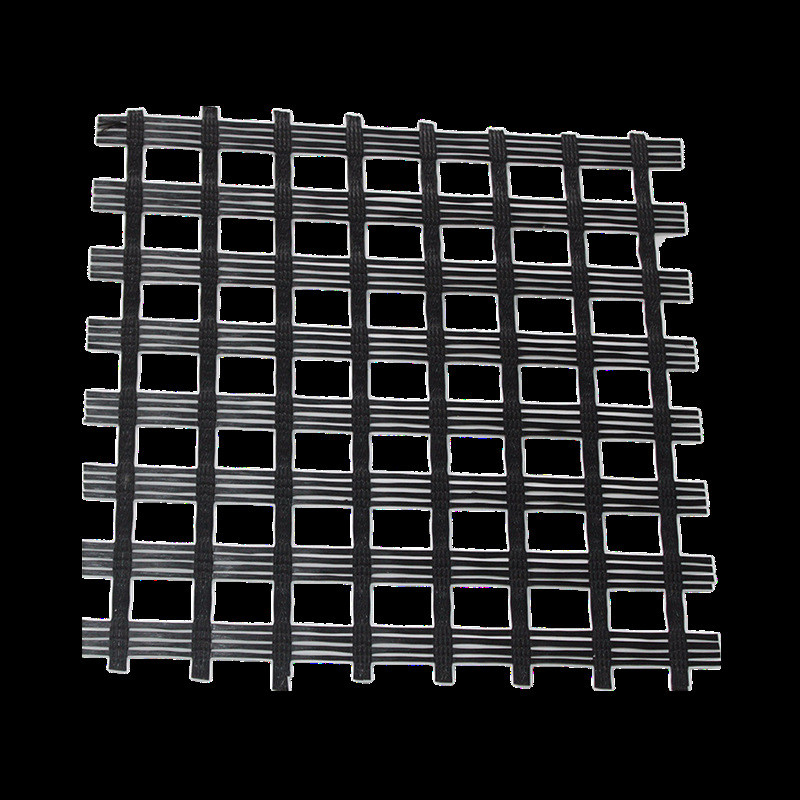

| Model | ZT30-30 | ZT50-50 | ZT60-60 | ZT80-80 | ZT100-100 | ZT120-120 | ZT150-150 | |

| Grid size(mm) | 25.4*25.4 or 12.7*12.7 | |||||||

| Breaking strength≥(kN/m) | Radial | 30 | 50 | 60 | 80 | 100 | 120 | 150 |

| Weft | 30 | 50 | 60 | 80 | 100 | 120 | 150 | |

| Elongation at break≤(%) | Radial | 4 | ||||||

| Weft | 4 | |||||||

| temperature resistance(℃) | -100~280 | |||||||

![]()

Features of Fiberglass Geogrid

1. High tensile strength and low elongation - glass fiber geogrid is made of glass fiber, which has high deformation resistance and elongation at a break of less than 3%.

2. Thermal stability - the melting temperature of glass fiber is above 1000 ℃, which ensures the thermal stability of glass fiber geogrid during the paving operation.

3. Physical and chemical stability - After being coated with special post-treatment agents, glass fiber geogrid can resist various physical wear and chemical erosion, as well as resist biological erosion and climate change, ensuring that its performance is not affected.

4. Aggregate interlocking and confinement - Since the fiberglass geogrid is a mesh structure, the aggregate in the asphalt concrete can penetrate through it, thus forming a mechanical interlocking. This restriction impedes the movement of the aggregate, enabling the asphalt mixture to achieve better compaction, higher load-bearing capacity, better load transfer performance, and less deformation under load.

![]()

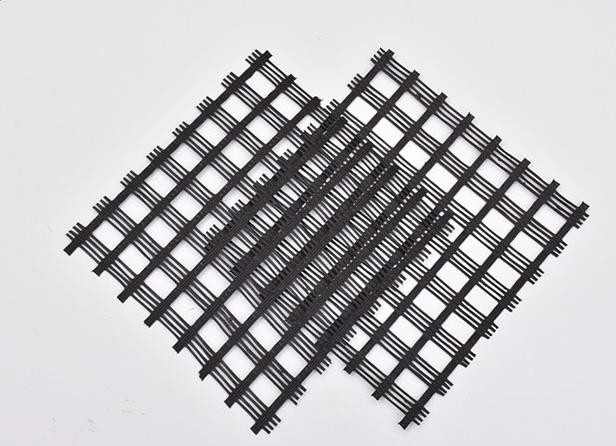

The construction method of Glass Fiberglass Geogrid

1. For old asphalt concrete pavement and old cement concrete pavement, make a leveling layer with a thickness of 20mm-30mm and use a vacuum truck or sprinkler to ensure that the road surface is clean.

2. Spray AH-70 or AH-90 heavy oil hot asphalt, the dosage should be 0.3kg-0.4kg/m2.

3. Use the special paver provided by our group to lay the self-adhesive fiberglass grating. The laying should be smooth and tight.

4. The horizontal lap length should be 50mm-100mm, the longitudinal lap length should be 150mm-200mm, and the overlapping direction of the lap should be consistent with the running direction of the asphalt concrete paver.

5. Use a rubber wheel roller for rolling (a rubber wheel roller needs to be equipped with a sprinkler).

Entire Service

We would provide customers with a one-year warranty, during processing, if customers have any problems with installation and use, we have professionals to provide online text, voice, or video communication services for them.