150kn Steel Plastic Composite Geogrid Machine For Slope Protection

-

Highlight

150kn Steel Plastic Composite Geogrid

,Composite Geogrid For Slope Protection

,geosynthetic steel plastic geogrid

-

Portrait Tension Force (kN/m)30-150

-

MaterialSteel

-

ConditionNew

-

Transport PackageWooden Box

-

After-sales ServiceTracking Guidance & Servic

-

WarrantyOne Year

-

ColorBlack

-

BrandZHONGTUO

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE; ISO

-

Minimum Order Quantity1PC

-

Packaging DetailsWooden Case

-

Delivery Time7-15Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

150kn Steel Plastic Composite Geogrid Machine For Slope Protection

Steel & Plastic Composite Geogrid 150kn for Slope Protection

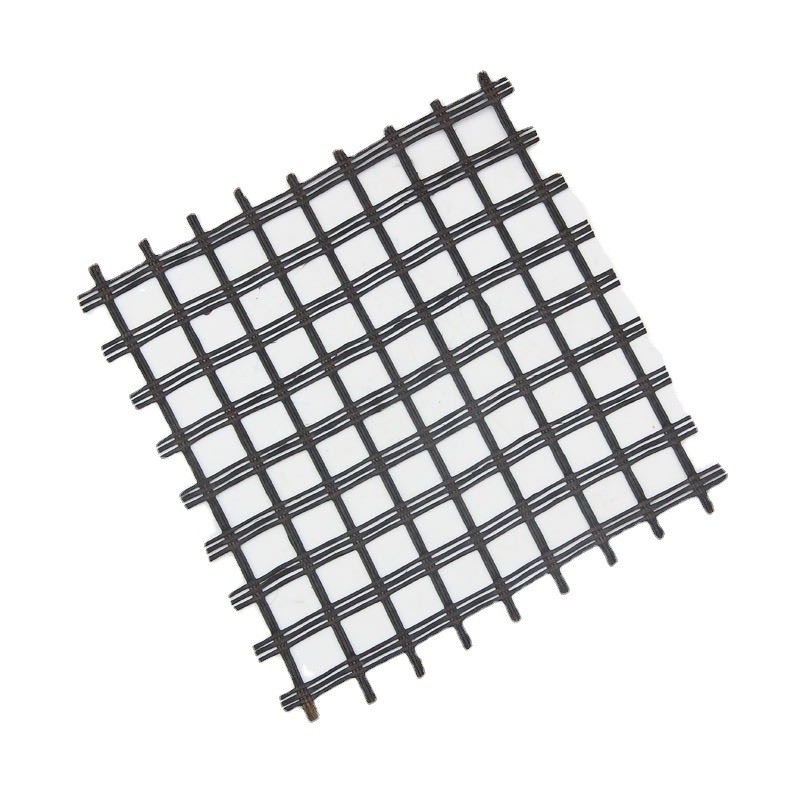

Description of Steel Plastic Geogrid

Geogrid is a major geosynthetic material, which has unique properties and efficacy compared with other geosynthetics. It is often used as a reinforcing material for reinforced soil structures or a reinforcing material for composite materials.

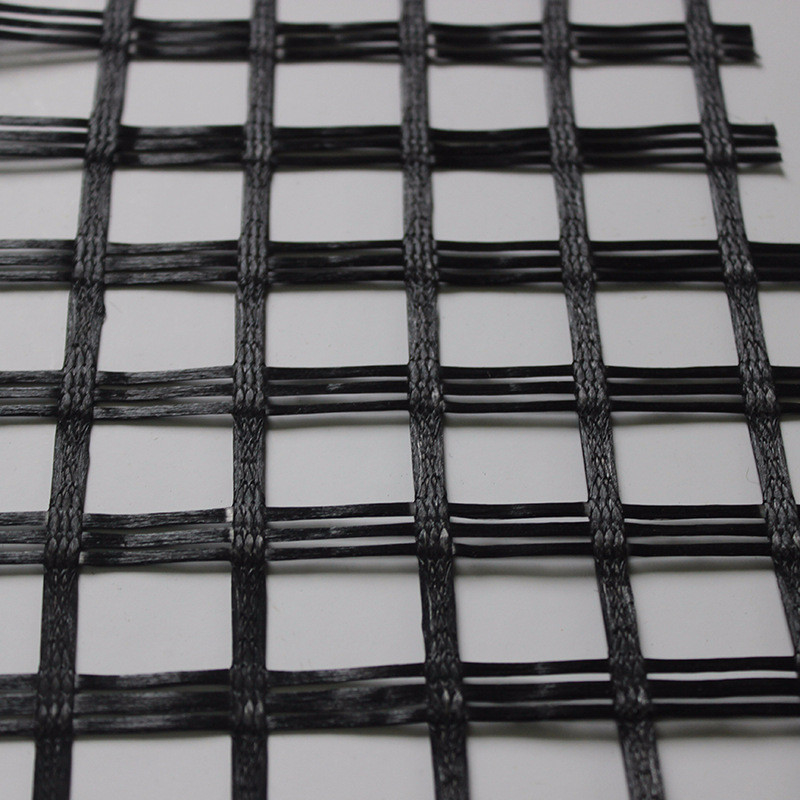

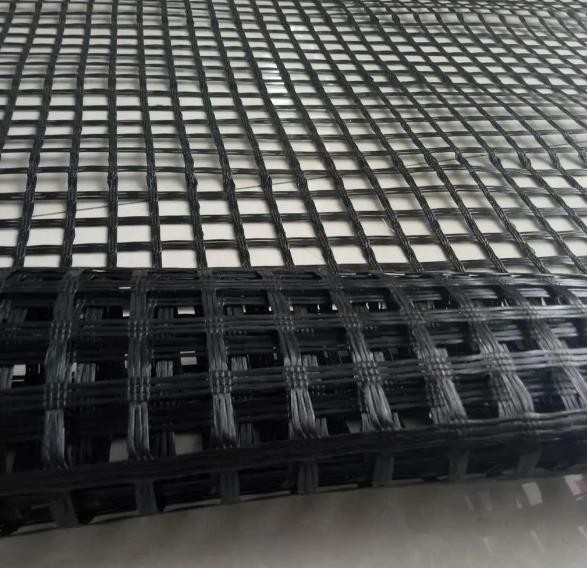

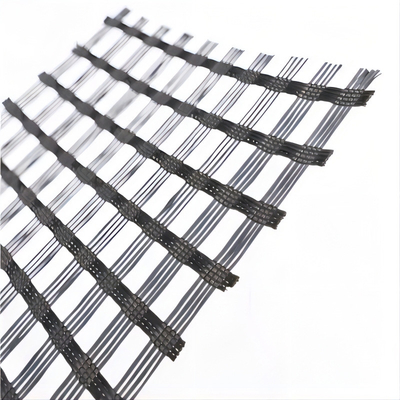

The steel plastic geogrid is made of high-strength steel wire (or other fibers), specially treated, and polyethylene (PE), and other additives are added to make it a composite high-strength tensile strip through extrusion, and the surface has a rough pressure pattern, it is a high-strength reinforced geotextile belt. From this, the single belt is woven or sandwiched at a certain distance vertically and horizontally, and its junction is formed by welding its junction with a special strengthening bonding fusion welding technology, which is a reinforced geogrid.

Technical Parameter of Steel Plastic Geogrid

| Item/Specification | ZT30-30 | ZT40-40 | ZT50-50 | ZT60-60 | ZT80-80 | ZT100-100 | ZT150-150 |

| Portrait Tension Force (kN/m) | 30 | 40 | 50 | 60 | 80 | 100 | 150 |

| Horizontal Tension Force (kN/m) | 30 | 40 | 50 | 60 | 80 | 100 | 150 |

| Tension Rate | 3 | ||||||

| Size(mm) | 1-6 | ||||||

![]()

Advantages of Steel Plastic Geogrid

1. Geogrid is used to increase the bearing capacity of the road (ground) foundation and prolong the service life of the road (ground) foundation.

2. Geogrid is used to prevent the road (ground) from collapsing or cracking and keep the ground beautiful and tidy.

3. Geogrids are used to enhance soil slopes and prevent soil erosion.

4. Geogrid is used to reduce the thickness of the cushion and save costs.

5. The geogrid is used to support the stable greening environment of the grass-planting mesh pad on the slope.

6. Geogrid can effectively block the transmission of seismic force and play an important role in enhancing the seismic stiffness, strength, and stability of the embankment.

![]()

Engineering Usages of Polyester Warp Knitted Geogrid

1. It has high strength, low creep, and can adapt to various environmental soils, which can fully meet the use of tall retaining walls in high-grade highways.

2. It can effectively improve the interlocking and occlusal effect of the reinforced bearing surface, greatly enhance the bearing capacity of the foundation, effectively restrain the lateral displacement of the soil, and enhance the stability of the foundation.

3. Compared with the traditional grid, it has the characteristics of high strength, strong bearing capacity, corrosion resistance, anti-aging, large friction coefficient, uniform holes, convenient construction, and long service life.

4. It is more suitable for deep-sea operations and reinforcement of embankments, and fundamentally solves the technical problems of low strength, poor corrosion resistance, and short service life caused by long-term erosion of seawater for gabions made of other materials.

5. It can effectively avoid construction damage caused by being crushed and damaged by the machine during the construction process.