-

Highlight

7.5kw Steel Bar Upsetting Machine

,Sawing Line Upsetting Machine

,Automatic Upset Forging Machine

-

Working Pressure31.5Mpa

-

Motor Power7.5kw

-

Weight400KG

-

ApplicationSteel Bar

-

After-sales ServiceTracking Guidance & Service

-

WarrantyOne Year

-

Transport PackageWooden Box

-

BrandZHONGTUO

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE; ISO

-

Minimum Order Quantity50

-

Packaging DetailsWooden Cases

-

Delivery Time7-15Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

7.5kw Automatic Steel Bar Upsetting Machine With Sawing Line

Description of Steel Bar Upsetting Machine

A fully automatic double-cylinder steel bar upsetting machine tool uses high pressure to make the head of the steel bar cold-pressed and plastically deformed, the diameter is increased, and then the thread is processed, so that the effective cross-section of the processed thread is larger than the base material of the steel bar, so as to improve the quality of the joint and make the joint compressive. , The tensile strength is greater than that of the base metal, this machine tool is suitable for connecting steel bars in national key projects with high requirements such as bridges and subways.

Advantages of Steel Bar Upsetting Machine

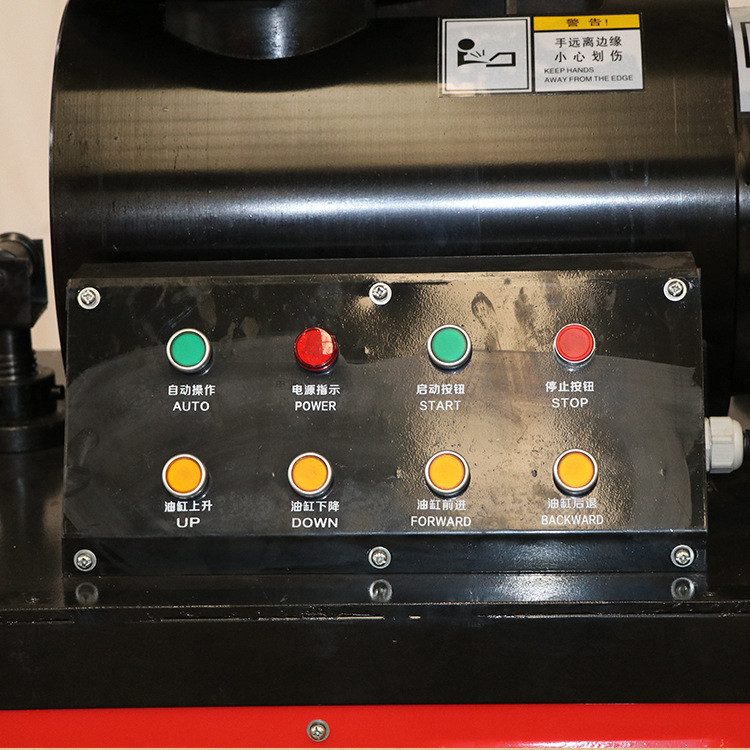

1. Simple operation, hydraulic electrical control, no need for professional technicians, and it can be turned on and operated after a short period of training.

2. Expand the cross-sectional area of the end of the steel bar by 15%-20%, so that the bottom diameter of the processed thread is not less than the diameter of the steel bar base material, and the tensile strength of the steel bar can be exerted by 110%.

3. High production efficiency, upsetting a steel bar head within 10-15 seconds.

4. It can process steel bars in a wide range, and can process steel bars of various specifications from 16 to 32 in accordance with GB1499 or GB1301 4 standards.

5. It has the advantages of being lightweight, pleasing appearance, fast speed, and flexible use.

6. Environmental protection, safety, and not being affected by the environment and climate.

Technical Parameters of Fully Automatic Double Cylinder Upsetting Machin

| Item | Parameter |

| Motor Power | 7.5KW |

| Processing range | 16-32 |

| Machine voltage | 380V |

| Machine size | L1300*W700*H1000 |

| Weight | 400KG |

| Working pressure | 31.5Mpa |

![]()

Instructions

(1) Preparation before processing:

1. Connect the power cord. The power supply is a three-phase four-wire. Before powering on, the fuselage must be connected to the ground wire.

2. Fill the oil tank with enough hydraulic oil, about 75 liters, and the oil level can be observed in the oil level gauge.

3. Check whether the components are flexible.

(2) No-load test run

1. Turn on the power, press the start button, and check whether the motor turns correctly. If not, change two phases of the three-phase power supply.

2. Operate the buttons and observe whether the actions of each button are consistent (Note: observe the automatic operation at the end)

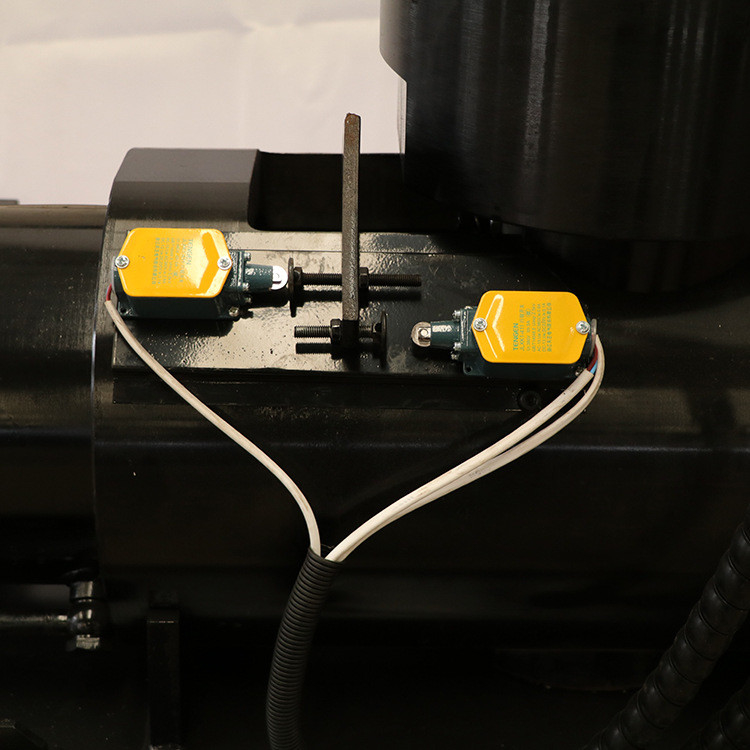

(3) Adjustment of the machine

1. Before processing, select the appropriate mold according to the steel bar's diameter.

2. Replace the mold: first remove the stroke limit bracket, press the back button of the oil cylinder to the initial position, press the upward button of the oil cylinder to make the lower pressure cylinder rise to the initial post, and remove the screws at both ends of the upper mold. The upper mold can be taken out in the middle, then the lower mold can be removed, and the pressure plate at the end can be taken out. The lower mold can be taken out in the middle, and the mold with the same diameter as the rebar can be installed according to the reverse operation of the above operation. Observe whether the upper mold runs flexibly, if not, remove and grind the sliding surface.