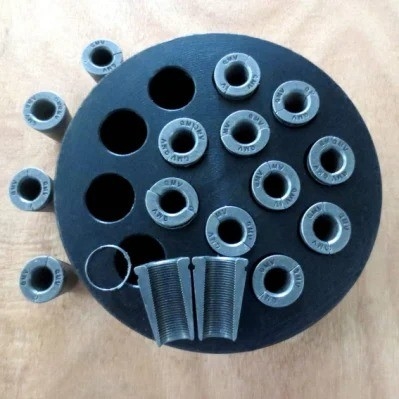

12.7 / 15.2 / 17.8mm Steel Wire Cable Tensioning Anchor Post Tension Mono / Multi Hole Anchorage

-

Highlight

Steel Wire Cable Tension Anchor

,Mono Post Tension Anchor

,17.8mm Post Tension Cable Anchors

-

AutomationSemi-automatic

-

PC Strand1-15holes

-

Product ShapeRound

-

Wedge Form2 Chip Or 3 Chips

-

CertificationCE; ISO

-

ApplicationBridge

-

WarrantyOne Year

-

MaterialAlloy Steel

-

Place of OriginChina

-

Brand NameZHONGTUO

-

CertificationCE; ISO

-

Minimum Order Quantity1

-

Packaging DetailsWooden Case

-

Delivery Time7-15Days

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

12.7 / 15.2 / 17.8mm Steel Wire Cable Tensioning Anchor Post Tension Mono / Multi Hole Anchorage

12.7/15.2/17.8mm steel wire cable tensioning anchor post-tension mono/multi-hole anchorage

Description of Strand Post Tension Round Flat Anchor

Anchorage is a permanent anchoring device used in prestressed concrete and is an integral part of applying the shrinkage force generated by the prestressed tendons to the construction. In post-tensioned structures or components, in order to maintain the tension of the prestressed tendons and transmit them to the inside of the concrete, the anchoring tool can improve the bearing capacity of the bridge, increase the span of the bridge, and reduce the weight of the bridge.

![]()

Specification of Strand Post Tension Round Flat Anchor

| Technical data of YJM13 Anchorage | ||||||||||

| Specification | Anchor Head | Bearing Plate | Duct | Spiral Reinforcement | Stressing Jack | |||||

| ΦA | B | Square | Round | ΦE(ID) | ΦF | H | ΦG | N | ||

| C*D | ΦC*D | |||||||||

| YJM13-1 | 38 | 40 | 80×10 | - | 35 | 80 | 30 | 6 | 3 | QYC270 |

| YJM13-2 | 76 | 42 | 115×80 | 120×80 | 45 | 120 | 40 | 8 | 3 | YDC1100 |

| YJM13-3 | 83 | 42 | 120×80 | 130×80 | 50 | 120 | 40 | 10 | 3 | YDC1100 |

| YJM13-4 | 87 | 42 | 130×87 | 135×85 | 50 | 135 | 50 | 10 | 3 | YDC1100 |

| YJM13-5 | 97 | 42 | 140×92 | 140×100 | 55 | 140 | 50 | 10 | 4 | YDC1100 |

| YJM13-6 | 107 | 45 | 150×97 | 150×125 | 60 | 160 | 50 | 12 | 4 | YDC1100 |

| YJM13-7 | 107 | 45 | 150×97 | 150×125 | 60 | 160 | 50 | 12 | 4 | YDC1100 |

| YJM13-8 | 117 | 45 | 165×115 | 165×135 | 60 | 170 | 50 | 12 | 4 | YDC1500 |

| YJM13-9 | 127 | 48 | 175×125 | 175×140 | 70 | 180 | 50 | 12 | 4 | YDC1500 |

| YJM13-10 | 136 | 48 | 180×130 | 180×150 | 80 | 200 | 50 | 14 | 4 | YDC2500 |

| YJM13-11 | 138 | 50 | 180×130 | 180×150 | 80 | 200 | 50 | 14 | 4 | YDC2500 |

| YJM13-12 | 143 | 50 | 190×140 | 190×150 | 80 | 210 | 50 | 14 | 5 | YDC2500 |

| YJM13-13 | 147 | 53 | 190×140 | 190×150 | 80 | 210 | 50 | 14 | 5 | YDC2500 |

| YJM13-14 | 153 | 53 | 195×150 | 200×160 | 80 | 220 | 50 | 14 | 5 | YDC2500 |

| YJM13-15 | 157 | 55 | 195×150 | 200×160 | 90 | 220 | 50 | 14 | 5 | YDC2500 |

| YJM13-16 | 167 | 55 | 210×160 | 210×185 | 90 | 240 | 60 | 16 | 6 | YDC2500 |

| YJM13-17 | 172 | 58 | 220×175 | 235×185 | 90 | 240 | 60 | 16 | 6 | YDC3500 |

| YJM13-18 | 176 | 58 | 235×175 | 235×185 | 90 | 260 | 60 | 16 | 6 | YDC3500 |

| YJM13-19 | 176 | 58 | 235×175 | 235×185 | 90 | 260 | 60 | 16 | 6 | YDC3500 |

| YJM13-20 | 196 | 60 | 270×185 | 260×200 | 90 | 270 | 60 | 16 | 6 | YDC3500 |

| YJM13-21 | 196 | 63 | 270×185 | 260×200 | 90 | 270 | 60 | 16 | 6 | YDC3500 |

| YJM13-22 | 196 | 65 | 270×185 | 260×200 | 90 | 270 | 60 | 18 | 6 | YDC3500 |

| YJM13-23 | 206 | 65 | 295×245 | 275×260 | 100 | 280 | 60 | 18 | 6 | YDC4000 |

| YJM13-24 | 206 | 68 | 295×245 | 275×260 | 100 | 280 | 60 | 18 | 6 | YDC4000 |

| YJM13-25 | 216 | 68 | 300×260 | 275×290 | 100 | 290 | 60 | 18 | 6 | YDC4000 |

| Technical data of YJM15 Anchorage | ||||||||||

| Specification | Anchor Head | Bearing Plate | Duct | Spiral Reinforcement | Stressing Jack | |||||

| ΦA | B | Square | Round | ΦE (ID) |

ΦF | H | ΦG | N | ||

| C×D | ΦC×D | |||||||||

| YJM15-1 | 43 | 46 | 80×12 | 80×20 | 35 | 80 | 30 | 8 | 4 | QYC270 |

| YJM15-2 | 83 | 48 | 130×85 | 135×80 | 50 | 120 | 40 | 10 | 4 | YDC6500 |

| YJM15-3 | 87 | 48 | 130×87 | 135×85 | 50 | 120 | 40 | 10 | 4 | YDC650 |

| YJM15-4 | 97 | 48 | 140×92 | 140×100 | 50 | 140 | 50 | 10 | 4 | YDC1100 |

| YJM15-5 | 107 | 48 | 150×97 | 150×120 | 55 | 150 | 50 | 10 | 4 | YDC1100 |

| YJM15-6 | 122 | 50 | 165×115 | 165×135 | 70 | 170 | 50 | 12 | 4 | YDC1500 |

| YJM15-7 | 122 | 50 | 175×125 | 175×135 | 70 | 170 | 50 | 12 | 4 | YDC1500 |

| YJM15-8 | 137 | 53 | 180×130 | 180×150 | 80 | 190 | 50 | 12 | 4 | YDC2500 |

| YJM15-9 | 147 | 53 | 190×140 | 190×150 | 80 | 200 | 50 | 12 | 4 | YDC2500 |

| YJM15-10 | 157 | 53 | 195×150 | 210×160 | 90 | 210 | 60 | 14 | 4 | YDC2500 |

| YJM15-11 | 157 | 55 | 210×160 | 210×160 | 90 | 210 | 60 | 14 | 4 | YDC2500 |

| YJM15-12 | 167 | 55 | 210×160 | 210×185 | 90 | 230 | 60 | 14 | 4 | YDC2500 |

| YJM15-13 | 177 | 55 | 220×175 | 210×185 | 90 | 230 | 60 | 14 | 4 | YDC3500 |

| YJM15-14 | 177 | 58 | 225×175 | 235×185 | 90 | 240 | 60 | 14 | 4 | YDC3500 |

| YJM15-15 | 187 | 60 | 235×175 | 235×185 | 90 | 260 | 60 | 16 | 5 | YDC3500 |

| YJM15-16 | 187 | 60 | 240×175 | 235×185 | 90 | 260 | 60 | 16 | 5 | YDC3500 |

| YJM15-17 | 197 | 63 | 250×185 | 265×200 | 100 | 280 | 60 | 16 | 5 | YDC4000 |

| YJM15-18 | 197 | 63 | 270×185 | 265×200 | 100 | 280 | 60 | 16 | 5 | YDC4000 |

| YJM15-19 | 197 | 63 | 270×185 | 265×200 | 100 | 280 | 60 | 16 | 5 | YDC4000 |

| YJM15-20 | 217 | 68 | 295×245 | 285×260 | 120 | 290 | 60 | 16 | 5 | YDC5000 |

| YJM15-21 | 217 | 70 | 295×245 | 285×260 | 120 | 290 | 60 | 16 | 5 | YDC5000 |

| YJM15-22 | 217 | 70 | 295×245 | 285×260 | 120 | 290 | 60 | 18 | 5 | YDC5000 |

| YJM15-23 | 237 | 73 | 310×260 | 320×260 | 120 | 320 | 60 | 18 | 5 | YDC5000 |

| YJM15-24 | 237 | 75 | 310×260 | 320×260 | 120 | 320 | 60 | 18 | 5 | YDC5000 |

| YJM15-25 | 237 | 78 | 310×300 | 320×300 | 120 | 330 | 70 | 18 | 5 | YDC6500 |

Main Classification of Bridge Anchorage

![]()

![]()

Main classification

(1) Round anchor

The specification model is expressed as: YJM15-N (YM15-N) or YJM13-N (YM13-N); this type of anchor has good self-anchoring performance. For tensioning, a through-center jack is generally used.

(2) Flat anchor

The specification model is expressed as: BJM15-N (BM15-N) or BJM13-N (BM13-N) (B, the first letter of the Chinese Pinyin for flat anchors, representing the meaning of flat anchors); flat anchors are mainly used for bridges The horizontal prestressed surface, hollow slab, and low-height box girder make the stress distribution more even and reasonable, and further reduce the thickness of the structure.

(3) Wrapped anchor

(Fixed end anchorage) The specification model is expressed as: JYM15-N (YMP15-N) or JYM13-N (YMP13-N); it is suitable for the situation where the design stress at the end of the component is large or the end space is restricted. It uses extrusion The machine presses the squeeze sleeve onto the stranded wire. It is pre-embedded in the concrete and arranged as required. After the concrete has solidified to the design strength, it is stretched.

Application Fields of Prestressed Tension Round Anchorage

Highway bridges, railway bridges, urban interchanges, urban light rails, high-rise buildings, water conservancy and hydropower dams, port terminals, rock mass slope protection anchoring, foundation reinforcement, tunnel mine roof anchor roof, prestressed grid, subway, large buildings, halls, Warehouse workshop, tower building, heavy lifting, sliding film intermittent propulsion, bridge, and tunnel jacking, large containers and ships, sleepers, replacement of bridge supports, bridge and building reinforcement, steel reinforcement works, anti-magnetic and anti-corrosion works (fiber anchors) ), carbon fiber reinforcement, pre-tensioned beam field construction, external prestressing engineering, stay cables, suspension cables, etc.

![]()

Notices of Prestressed Tension Round Anchorage

(1) For the cutting of prestressed ribs, a grinding wheel saw should be used, and arc cutting should not be used;

(2) When the steel strands are bundled, they should be straightened out one by one, bundled into bundles, and must not be disordered. The extruded anchorage or embossed anchorage at the fixed end of the steel strand shall be assembled with the bearing plate and spiral reinforcement in advance;

(3) The equipment and instruments used for prestressing shall be regularly maintained and calibrated;

(4) Before the prestressed tendons are tensioned, the concrete strength and compression test report shall be provided. When the compressive strength of concrete meets the design requirements and is not lower than 75% of the design strength grade, prestressing can be applied;

(5) Before the prestressing tendons are tensioned, the surface of the bearing plate should be cleaned and the quality of the concrete behind the bearing plate should be checked. If there is a cavity in the concrete, it should be repaired with epoxy mortar before tensioning;

(6) When the anchor is installed, the anchor plate should be straight, the clip should be tightened, and the position of the clip should be uniform: but the clip should not be beaten too hard when tightening the clip, so as not to damage the clip.