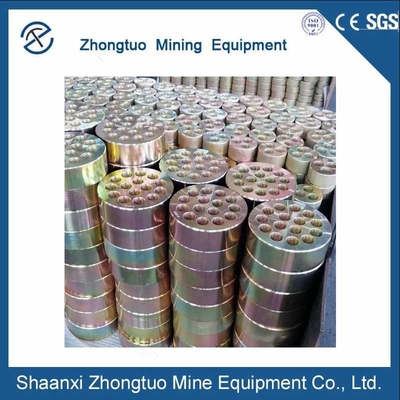

Post Tension Round Flat Anchor Multi Holes Multi-Specification Large Quantity Supply

-

Highlight

Ductile Iron Multi Holes Anchor

,Post Tension Round Flat Anchor

-

PC Strand1-15holes

-

Transport PackageWooden Box

-

CertificationCE; ISO

-

After-sales ServiceTracking Guidance & Service

-

WarrantyOne Year

-

MaterialDuctile Iron

-

Place of OriginCN

-

Brand NameZHONGTUO

-

CertificationCE, ISO and SGS

-

Pricenegotiable

-

Delivery Time1-2 weeks

-

Payment TermsL/C, D/A, D/P, T/T, Western Union, MoneyGram

Post Tension Round Flat Anchor Multi Holes Multi-Specification Large Quantity Supply

Anchorage is a permanent anchoring mechanism used in prestressed concrete that is critical in applying the shrinkage force generated by the prestressed tendons to the structure. The anchoring tool in post-tensioned structures or components can improve the bridge's bearing capacity, lengthen its span, and lower its weight by maintaining the tension of the prestressed tendons and transmitting it to the inside of the concrete.

![]()

Specification of Strand Post Tension Round Flat Anchor

| Technical data of YJM13 Anchorage | ||||||||||

| Specification | Anchor Head | Bearing Plate | Duct | Spiral Reinforcement | Stessing Jack | |||||

| ΦA | B | Square | Round | ΦE(ID) | ΦF | H | ΦG | N | ||

| C*D | ΦC*D | |||||||||

| YJM13-1 | 38 | 40 | 80×10 | - | 35 | 80 | 30 | 6 | 3 | QYC270 |

| YJM13-2 | 76 | 42 | 115×80 | 120×80 | 45 | 120 | 40 | 8 | 3 | YDC1100 |

| YJM13-3 | 83 | 42 | 120×80 | 130×80 | 50 | 120 | 40 | 10 | 3 | YDC1100 |

| YJM13-4 | 87 | 42 | 130×87 | 135×85 | 50 | 135 | 50 | 10 | 3 | YDC1100 |

| YJM13-5 | 97 | 42 | 140×92 | 140×100 | 55 | 140 | 50 | 10 | 4 | YDC1100 |

| YJM13-6 | 107 | 45 | 150×97 | 150×125 | 60 | 160 | 50 | 12 | 4 | YDC1100 |

| YJM13-7 | 107 | 45 | 150×97 | 150×125 | 60 | 160 | 50 | 12 | 4 | YDC1100 |

| YJM13-8 | 117 | 45 | 165×115 | 165×135 | 60 | 170 | 50 | 12 | 4 | YDC1500 |

| YJM13-9 | 127 | 48 | 175×125 | 175×140 | 70 | 180 | 50 | 12 | 4 | YDC1500 |

| YJM13-10 | 136 | 48 | 180×130 | 180×150 | 80 | 200 | 50 | 14 | 4 | YDC2500 |

| YJM13-11 | 138 | 50 | 180×130 | 180×150 | 80 | 200 | 50 | 14 | 4 | YDC2500 |

| YJM13-12 | 143 | 50 | 190×140 | 190×150 | 80 | 210 | 50 | 14 | 5 | YDC2500 |

| YJM13-13 | 147 | 53 | 190×140 | 190×150 | 80 | 210 | 50 | 14 | 5 | YDC2500 |

| YJM13-14 | 153 | 53 | 195×150 | 200×160 | 80 | 220 | 50 | 14 | 5 | YDC2500 |

| YJM13-15 | 157 | 55 | 195×150 | 200×160 | 90 | 220 | 50 | 14 | 5 | YDC2500 |

| YJM13-16 | 167 | 55 | 210×160 | 210×185 | 90 | 240 | 60 | 16 | 6 | YDC2500 |

| YJM13-17 | 172 | 58 | 220×175 | 235×185 | 90 | 240 | 60 | 16 | 6 | YDC3500 |

| YJM13-18 | 176 | 58 | 235×175 | 235×185 | 90 | 260 | 60 | 16 | 6 | YDC3500 |

| YJM13-19 | 176 | 58 | 235×175 | 235×185 | 90 | 260 | 60 | 16 | 6 | YDC3500 |

| YJM13-20 | 196 | 60 | 270×185 | 260×200 | 90 | 270 | 60 | 16 | 6 | YDC3500 |

| YJM13-21 | 196 | 63 | 270×185 | 260×200 | 90 | 270 | 60 | 16 | 6 | YDC3500 |

| YJM13-22 | 196 | 65 | 270×185 | 260×200 | 90 | 270 | 60 | 18 | 6 | YDC3500 |

| YJM13-23 | 206 | 65 | 295×245 | 275×260 | 100 | 280 | 60 | 18 | 6 | YDC4000 |

| YJM13-24 | 206 | 68 | 295×245 | 275×260 | 100 | 280 | 60 | 18 | 6 | YDC4000 |

| YJM13-25 | 216 | 68 | 300×260 | 275×290 | 100 | 290 | 60 | 18 | 6 | YDC4000 |

| Technical data of YJM15 Anchorage | ||||||||||

| Specification | Anchor Head | Bearing Plate | Duct | Spiral Reinforcement | Stressing Jack | |||||

| ΦA | B | Square | Round | ΦE (ID) |

ΦF | H | ΦG | N | ||

| C×D | ΦC×D | |||||||||

| YJM15-1 | 43 | 46 | 80×12 | 80×20 | 35 | 80 | 30 | 8 | 4 | QYC270 |

| YJM15-2 | 83 | 48 | 130×85 | 135×80 | 50 | 120 | 40 | 10 | 4 | YDC6500 |

| YJM15-3 | 87 | 48 | 130×87 | 135×85 | 50 | 120 | 40 | 10 | 4 | YDC650 |

| YJM15-4 | 97 | 48 | 140×92 | 140×100 | 50 | 140 | 50 | 10 | 4 | YDC1100 |

| YJM15-5 | 107 | 48 | 150×97 | 150×120 | 55 | 150 | 50 | 10 | 4 | YDC1100 |

| YJM15-6 | 122 | 50 | 165×115 | 165×135 | 70 | 170 | 50 | 12 | 4 | YDC1500 |

| YJM15-7 | 122 | 50 | 175×125 | 175×135 | 70 | 170 | 50 | 12 | 4 | YDC1500 |

| YJM15-8 | 137 | 53 | 180×130 | 180×150 | 80 | 190 | 50 | 12 | 4 | YDC2500 |

| YJM15-9 | 147 | 53 | 190×140 | 190×150 | 80 | 200 | 50 | 12 | 4 | YDC2500 |

| YJM15-10 | 157 | 53 | 195×150 | 210×160 | 90 | 210 | 60 | 14 | 4 | YDC2500 |

| YJM15-11 | 157 | 55 | 210×160 | 210×160 | 90 | 210 | 60 | 14 | 4 | YDC2500 |

| YJM15-12 | 167 | 55 | 210×160 | 210×185 | 90 | 230 | 60 | 14 | 4 | YDC2500 |

| YJM15-13 | 177 | 55 | 220×175 | 210×185 | 90 | 230 | 60 | 14 | 4 | YDC3500 |

| YJM15-14 | 177 | 58 | 225×175 | 235×185 | 90 | 240 | 60 | 14 | 4 | YDC3500 |

| YJM15-15 | 187 | 60 | 235×175 | 235×185 | 90 | 260 | 60 | 16 | 5 | YDC3500 |

| YJM15-16 | 187 | 60 | 240×175 | 235×185 | 90 | 260 | 60 | 16 | 5 | YDC3500 |

| YJM15-17 | 197 | 63 | 250×185 | 265×200 | 100 | 280 | 60 | 16 | 5 | YDC4000 |

| YJM15-18 | 197 | 63 | 270×185 | 265×200 | 100 | 280 | 60 | 16 | 5 | YDC4000 |

| YJM15-19 | 197 | 63 | 270×185 | 265×200 | 100 | 280 | 60 | 16 | 5 | YDC4000 |

| YJM15-20 | 217 | 68 | 295×245 | 285×260 | 120 | 290 | 60 | 16 | 5 | YDC5000 |

| YJM15-21 | 217 | 70 | 295×245 | 285×260 | 120 | 290 | 60 | 16 | 5 | YDC5000 |

| YJM15-22 | 217 | 70 | 295×245 | 285×260 | 120 | 290 | 60 | 18 | 5 | YDC5000 |

| YJM15-23 | 237 | 73 | 310×260 | 320×260 | 120 | 320 | 60 | 18 | 5 | YDC5000 |

| YJM15-24 | 237 | 75 | 310×260 | 320×260 | 120 | 320 | 60 | 18 | 5 | YDC5000 |

| YJM15-25 | 237 | 78 | 310×300 | 320×300 | 120 | 330 | 70 | 18 | 5 | YDC6500 |

Highway bridges, railway bridges, urban interchanges, urban light rails, high-rise buildings, water conservancy and hydropower dams, port terminals, rock mass slope protection anchoring, foundation reinforcement, tunnel mine roof anchor roof, prestressed grid, subway, large buildings, halls, warehouse workshop, tower building, heavy lifting, sliding film intermittent propulsion, bridge and tunnel jacking, large containers and ships, sleepers, bridge support replacement.

1. Tension end anchor: A tensionable anchor inserted at the end of a strand, also known as a prestressed anchor (round anchor, flat anchor).

(1) Round anchor: provides good anchoring and self-anchoring performance.

The round anchor has a good market and is disposable, and the general tension uses a hollow jack.

2) Flat anchors: Flat anchors are primarily utilized for lateral prestressing on bridge decks.

Hollow slabs and low-height box girders ensure a more homogeneous and appropriate stress distribution, further refining the structure.

2: Fixed-end anchor: Installed at the opposite end of the stranded wire, typically buried in concrete, and does not require a pull-end anchor (P anchor). P-type anchors are sometimes known as squeeze anchors.

![]()

The general anchorage building and installation method involves placing a small amount of explosives at the bottom of the hole, expanding it into a spherical shape after multiple anchorage constructions and installations, and finally inserting the explosives into the anchorage construction and installation. Compared to the hole anchorage construction and installation technique, this method has the following advantages: good anchoring construction and installation effect, high work efficiency, rapid progress, and low explosive consumption. This approach is commonly used to create and install short pile anchors for shallow foundations.

1. The anchors should be carefully stored, with no rust, water, or other sundries in use.

2. Before using the tool clip, lubricate the outer surface and the inner surface of the anchor plate's taper hole, and regularly remove dirt from the clip's surface.

3. Safety precautions must be followed during tensioning, and no one may stand after the tensioning jack.

4. The anchor system must be used jointly and cannot be combined with other systems.