-

Highlight

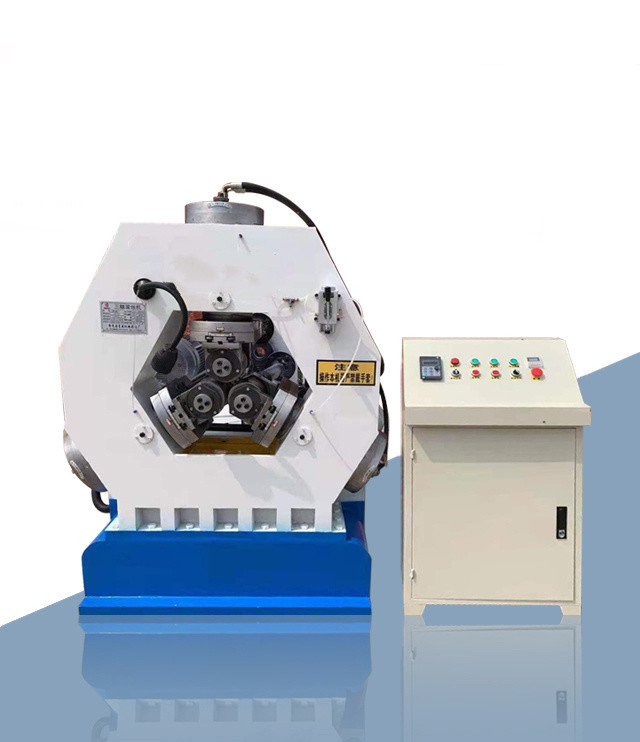

Hydraulic Thread Rolling Machine

,Three Axis Thread Rolling Machine

,Thread Rolling Rebar Processing Machine

-

Warranty12 Months

-

CustomizedCustomized

-

AdvantageEasy To Maintenance

-

ConditionNew

-

Transport PackageWooden Case

-

OriginChina

-

HS Code8463200000

-

Package Size Per Unit Product1950.00cm * 1050.00cm * 1070.00cm

-

Gross Weight Per Unit Product50.000kg

-

Shipping CostTo Be Negotiated

-

After-sales ServiceContact With E-Mail, Video, What′s APP

-

TypeRolling Machine

-

CertificationISO9001, CE

Hydraulic Three Axis Thread Rolling Machine

Product Description

Company Info.

Basic Info.

Packaging & Delivery

Product Description

Description:

The thread rolling machine is a multi-functional cold extrusion-forming machine tool. The thread rolling machine can process the thread, straight grain, and oblique grain rolling of the workpiece in a cold state within its rolling pressure range; straight teeth, helical teeth, and helical spline gears rolling; straightening, reducing, rolling and various forming rolling. The machine has a safe and reliable electric-hydraulic execution and control system, which allows each working cycle to be selected from three modes: manual, semi-automatic and automatic.

|

Item |

Parameter |

||

|

Model |

ZP28-125 |

Processing Diameter

|

Ø25-120mm |

|

Main drive motor |

15kw |

Rolling pitch |

1-16mm |

|

Hydraulic motor station |

5.5kw-4 |

Speed |

0-50r/min |

|

Roller Diameter |

Ø125-Ø180mm |

Unit quality |

3500kg |

|

Dimensions |

2000×1500×1700mm |

||

Features:

Thread Rolling Machine casting structure, three hydraulic cylinders are designed inside the fuselage, reasonable and strong, with large power, high precision thread processing, convenient adjustment, frequency conversion speed regulation, wide application range, can roll various threads, ordinary threads, T-shaped thread, net pattern, straight pattern, special-shaped thread, hollow anchor rod, hollow jacking, can also perform hydraulic processing such as forming and calendering on the workpiece.

The solution to the problem of no thread or messy thread

The direction of rotation of the rolling head is incorrect; the specification of the rolling head is inconsistent with the steel bar;

The order of the positioning sleeve is incorrect; whether the order of the rolling heads is installed correctly;

The roller and the positioning sleeve are damaged;

Wear & Refurbishment

The rolling wheels must be adjusted synchronously, that is, to adjust the coincidence of the indentations of the L and R wheels on the surface of the workpiece. If the synchronous adjustment is inaccurate, the workpiece will have chaotic teeth, chips, and out-of-tolerance conditions. The center height of the workpiece is consistent with the center height of the rolling wheel (allowing a lower 0.01-0.08mm). The commonly used adjustment methods are:

After the rolling wheel is worn out, the teeth can be ground off to reduce the number of teeth, and the parameters can be calculated again according to the above process, and the teeth can be re-cut to produce a refurbished rolling wheel, which can be refurbished multiple times within the allowable range of the center distance of the machine tool.