-

Highlight

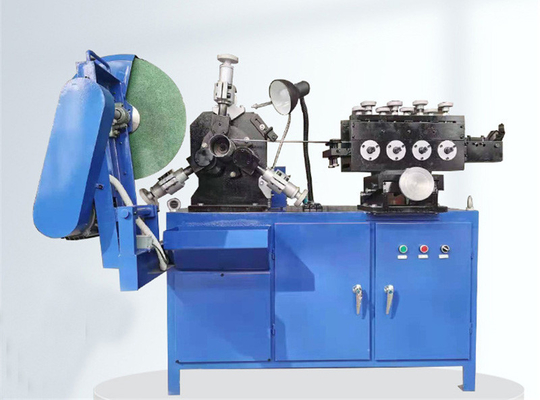

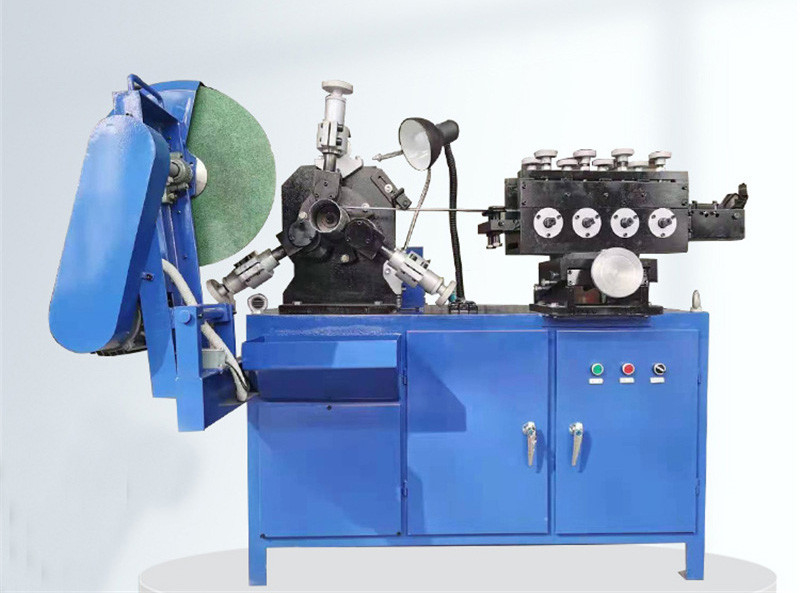

Deformed Steel Bar Making Machine

,Rebar Cold Rolled Bar Making Machine

,1430r/Min Rebar Making Machine

-

Strip Width36mm

-

ColorCustomized

-

Power3kw

-

Rotating Speed1430r/min

-

Weight576kg

-

Size1100x800x1360mm

-

Place of OriginShaanxi

-

Brand NameZHONGTUO

-

CertificationCE; ISO

-

Minimum Order Quantity1PC

-

Packaging DetailsWooden Case

-

Delivery Time7-15Days

Rebar Cold Rolled Deformed Steel Bar Making Machine

Description Steel Bar Making Machine

The Steel Bar Making Machine is the equipment for the production of metal bellows with prestressed concrete reserved channels. It adopts galvanized or cold-rolled steel strip (black belt) to roll into double waveforms and buckles the undercut to form bellows. The machine is small in size and high in efficiency. Simple operation and maintenance, suitable for centralized use in construction sites or factories.

Feature of Steel Bar-Making Machine

1. Prestressed metal corrugated pipe machine Spiral tube bundle pipe machine is practical: the pipe-making machine is the equipment for producing metal corrugated pipe with prestressed concrete reserved holes. Buckle to form bellows;

2. This machine is small in size, high in efficiency, and easy to operate; it can be used in construction sites or factories;

3. Prestressed metal bellows machine spiral tube bundle tube machine function and characteristics

4. This machine is easy to learn and understand.

Technical Parameter of Steel Bar-Making Machine

| Item | Parameter |

| Main Motor Power | 3kw |

| Rotating speed |

1430r/min |

| Cutting motor power |

0.75kw |

| Rotating speed |

1380r/min |

| Strip width |

36mm |

| Strip thickness |

0.2-0.35mm |

| Coil diameter range |

35-135mm |

| Weight |

576kg |

| Size |

1100x800x1360mm |

Application

![]()

Advantages of Steel Bar Making Machine

1. Both right-handed threads & left-handed threads could be processed with one machine head.

2. Processing speed, high degree of automation.

3. Convenient operation, service life is long,

4. The thread rolling round joint additional cost is low.

5. Environment-friendly, safe, with no environmental and weather restrictions.