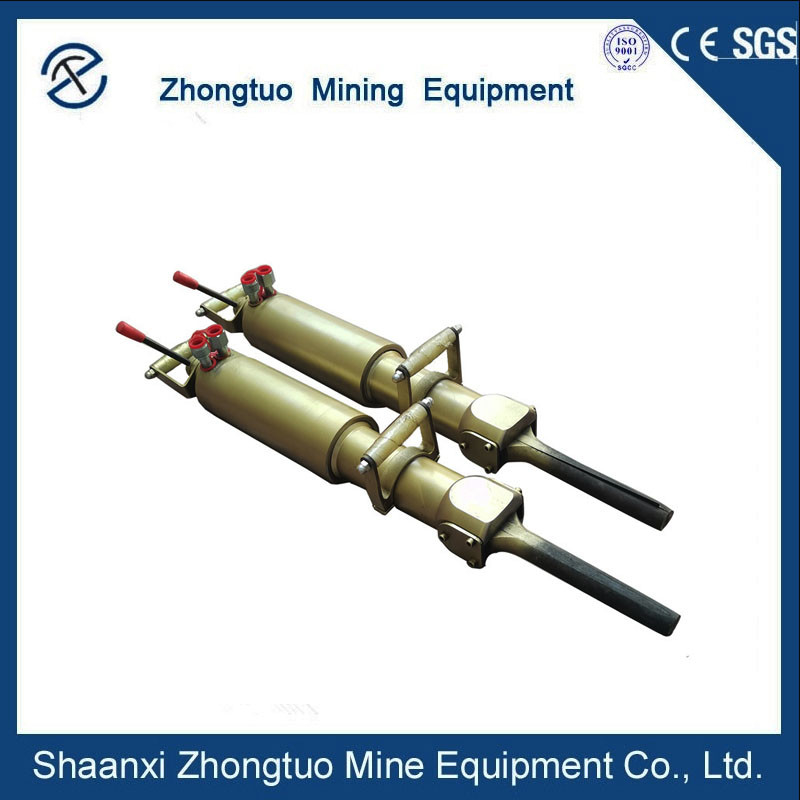

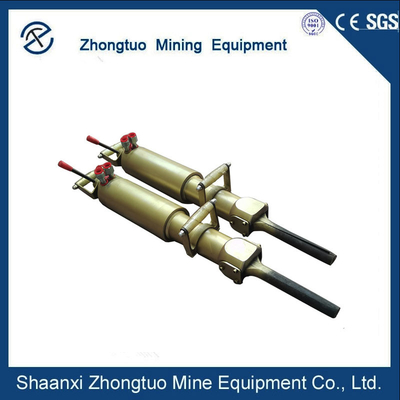

High Pressure Hydraulic Rock Splitter Machine With Cement Mortar Grout Properties Of Hydraulic Oil

-

Highlight

HighPressure Hydraulic Rock Splitter Machine

,High Pressure Rock Splitter Machine

,Steel Hydraulic Stone Splitter

-

ApplicationMining

-

ColorGrey

-

DurabilityHigh

-

FunctionSplitting Rocks

-

MaintenanceLow

-

MaterialSteel

-

NameRock Splitter Machine

-

Noise LevelLow

-

PowerElectric

-

SizeMedium

-

SpeedHigh

-

TypeHydraulic

-

Warranty1 Year

-

Place of OriginCN

-

Brand NameZT

High Pressure Hydraulic Rock Splitter Machine With Cement Mortar Grout Properties Of Hydraulic Oil

![]()

Introducing the Hydraulic Double-Piston Concrete Pump Grouting Pump with Cement Mortar Grout. This high-quality product is designed with the latest features to improve efficiency and productivity. The wedges are placed into a drilled hole, and when the splitter is operated, the power pack produces high-pressure oil to drive the piston of the splitter cylinder. The middle wedge is then pushed down, forcing two counter wedges against the wall of the hole. This results in a crack being developed due to the expansion of the counter wedges. The cracking direction of the rock/concrete is the same as that of the splitter handle. To use this product, the first step is to drill the necessary holes in the rock/concrete with the appropriate diameter and length. The wedge group of cylinders is then placed into the hole, and the position is checked before starting the splitter. This product is suitable for various applications such as smelting production, overhaul engineering, and various rescue and rescue fields. The hydraulic splitting machine uses the physical properties of hydraulic oil to be non-compressible and movable, adding static thrust to ensure security. Invest in the Hydraulic Double-Piston Concrete Pump Grouting Pump with Cement Mortar Grout for a professional and efficient way to improve your productivity.

Working Theory

The wedges are placed into a drilled hole. When a splitter is operated, the power pack produces high-pressure oil to drive the piston of the splitter cylinder which in turn pushes the middle wedge down. The downward movements of the middle wedge force two counter wedges against the wall of the hole. When the tension increases beyond the material's tensile strength.

Step 1: Drill the holes in the rock/concrete required to split of suitable diameter and length.

Step 2: Put the wedge group of cylinders into the hole. Check the position before starting the splitter.

Step 3: Once the splitter is initiated, a crack will be developed due to the expansion of counter wedges. The cracking direction of the rock/concrete is the same as that of the splitter handle.

Applicable fields

Hydraulic splitting machines have been widely used in the mining industry, construction engineering, demolition engineering, chemical industry, smelting production and overhaul engineering, and various rescue and rescue fields.

Advantages

1. Security: The hydraulic splitting machine uses the physical properties of hydraulic oil to be non-compressible and movable and adds static thrust to complete the task of static controllability.

2. Eco-friendly: There is no vibration, impact, noise, dust, or flying debris in the whole process.

3. Efficiency: machine completes one task within 10 -15 seconds with powerful splitting force (the rock splitting tonnage can reach 840t), and can continue to work continuously with high efficiency.

4. Application flexibility: The splitting machine has a small volume, lightweight, and compact structure. It ensures that the application method is easy to learn, and just one person is required to operate it.

![]()

![]()

![]()

Parameter

| Model | Drilling diameter(mm) | Drilling depth(mm) | Theoretical split(t) | Piston stroke (mm) | Splitting time | Wedge length(mm) |

| 250 | 38 | 450 | 800 | 90-200 | 10-15s | 250 |

| 350 | 42 | 550 | 820 | 90-200 | 10-15s | 350 |

| 450 | 50 | 650 | 840 | 90-200 | 10-15s |

450

|

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

FAQ:

Q1: Whether the rig is used for rock holes or soil holes?

A1: Equipped with different drill bits according to the application object. Rock drilling rigs are equipped with round steel drill impact hammers and rock drill bits. The soil drilling rigs require a twist drill pipe and a three-blade drill bit.

Q2: How much tonnage can a bridge jack lift??

A2: The range is from 50 to 1000 tons, depending on the application needs we have the right choice for you.

Q3: How many meters is the connection between the jack and the oil pump?

A3: The factory standard is two meters. If you need longer, we will make it for you.

Q4: What is the difference between the hydraulic oil pump?

A4: For the tension jack, it is a 50 MPa 3 kW oil pump and 60 MPa 4 kW oil pump.

Q5: What kind of packages does a set of anchors have?

A5: Anchor ring, clip, anchor pad, spiral rib.

Q6: Which payment term can you accept?

A6: 100% T/T( Decide according to actual situation)

Q7: How long is the machine warranty?

A7: One year for the machine and provide technical support according to your needs.

Q8: How long will it take to arrange production?

A8: we can deliver the normal goods within 7-15 days. Other nonstandard electrical items we will deliver within 25-30 days.

Q9: Which trade term can you accept?

A9: Available trade terms: FOB, CIF, CFR, EXW, etc.

Q10: Do you provide samples? Is it free or extra?

A10: Yes, we could offer you the sample machine. But it's not free. You need to pay for the sample and the cost of the freight.

Q11: What are your terms of payment?

A11: We accept T/T, Western Union, Money Gram, Paypal, L/C, etc.

Why you choose us:

1. We are a real factory offering products and providing free technical advice.

2. Company in business for many years and served Over 50 countries' customers.

3. All machines with CE, ISO, and SGS certificates. Machine and spindle warranty 1 year.

4. We have phone support in English, if you have any questions, you can call us, and we can give you the best solution within 24 hours.

5. Fast delivery, save your time.