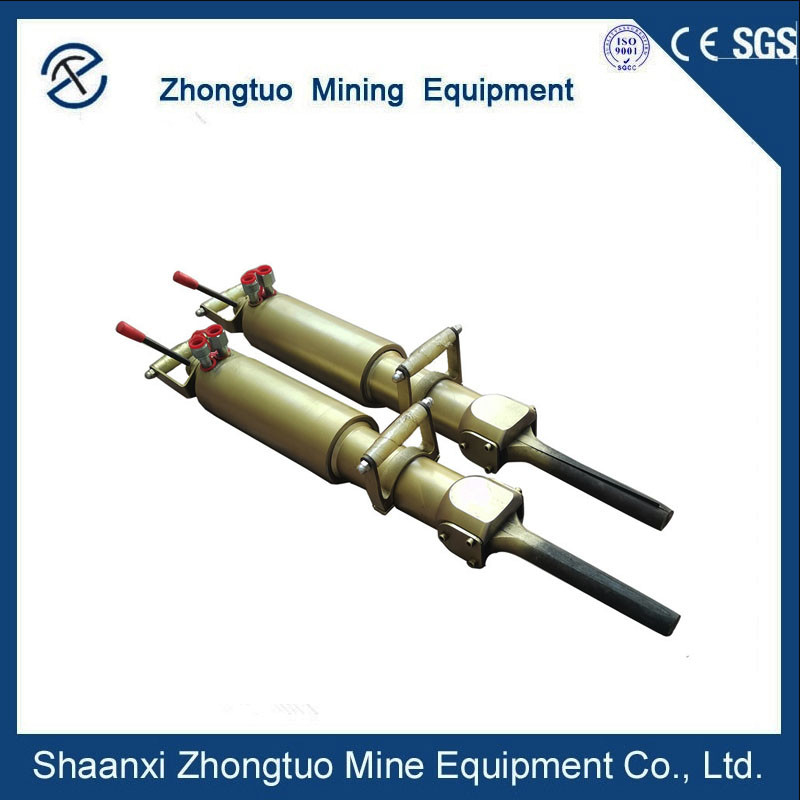

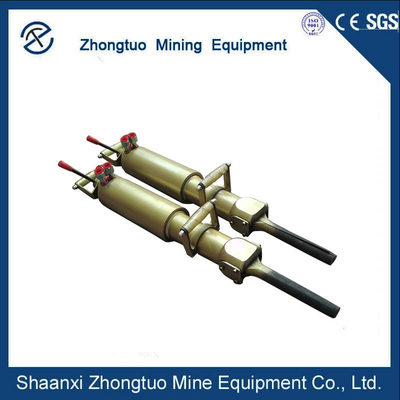

Hydraulic Stone Splitter Tool With High Pressure Property National Classified Certification

-

Highlight

High Pressure Stone Splitter Tool

-

ApplicationMining

-

DurabilityHigh

-

FunctionSplitting Rocks

-

MaterialSteel

-

Noise LevelLow

-

PowerElectric

-

SizeMedium

-

SpeedHigh

-

TypeHydraulic

-

Warranty1 Year

-

Place of OriginCN

-

Brand NameZT

-

CertificationCE, ISO and SGS

Hydraulic Stone Splitter Tool With High Pressure Property National Classified Certification

Introducing the Hydraulic Double-Piston Concrete Pump Grouting Pump for Cement Mortar Grout. This high-quality device includes cutting-edge features that boost efficiency and production. The wedges are inserted into a drilled hole, and when the splitter is turned on, the power pack generates high-pressure oil to drive the splitter piston. The middle wedge is then pushed down, forcing two counter-wedges on the hole's wall. The counter wedges expand, causing a crack to form. The cracking direction of the rock/concrete is identical to that of the splitter handle. To utilize this product, first drill the necessary holes in the rock/concrete with the proper diameter and length.

The wedge group of cylinders is then inserted into the hole and verified for alignment before the splitter is started. This product is appropriate for a variety of applications, including smelting production, overhaul engineering, and various rescue and recovery industries. The hydraulic splitting machine makes use of the physical qualities of hydraulic oil, which are non-compressible and moveable, and adds static thrust for security. Purchase the Hydraulic Double-Piston Concrete Pump Grouting Pump with Cement Mortar Grout for a professional and effective solution to boost your productivity.

| Model | Drilling diameter(mm) | Drilling depth(mm) | Theoretical split(t) | Piston stroke (mm) | Splitting time | Wedge length(mm) |

| 250 | 38 | 450 | 800 | 90-200 | 10-15s | 250 |

| 350 | 42 | 550 | 820 | 90-200 | 10-15s | 350 |

| 450 | 50 | 650 | 840 | 90-200 | 10-15s | 450 |

The wedges are inserted into a drilled hole. When a splitter is turned on, the power pack generates high-pressure oil, which drives the piston of the splitter cylinder, pushing the middle wedge down. The downward movements of the middle wedge press two counter wedges against the hole's wall. When the tension exceeds the material's tensile strength.

1. Drill holes of appropriate diameter and length in the rock/concrete required to split.

2. Place the wedge group of cylinders in the hole. Before you begin using the splitter, double-check the position.

3: Once the splitter is started, a crack will form owing to the expansion of the counter wedges. The cracking direction of the rock/concrete is identical to that of the splitter handle.

Hydraulic splitting machines have found widespread application in the mining industry, construction engineering, demolition engineering, chemical industry, smelting production and overhaul engineering, and various rescue and rescue industries.

1. Security: The hydraulic splitting machine takes advantage of the physical qualities of hydraulic oil, which are non-compressible and moveable, and adds static thrust to fulfill the duty of static control.

2. Environmentally friendly: There is no vibration, impact, noise, dust, or flying debris in the entire process.

3. Efficiency: The machine completes one duty in 10 -15 seconds with a tremendous splitting force (the rock splitting tonnage may reach 840t) and can work continuously at high efficiency.

4. Application versatility: The splitting machine has a tiny, lightweight, and compact design. It assures that the application method is simple to understand, and that only one person is necessary to execute it.

![]()

![]()

![]()

![]()

![]()

![]()